Perovskite solar cells have been generating a tremendous amount of excitement over the past few years. They are made from an entirely new class of materials and efficiencies have risen faster than for any other type of solar cell to date. One of the components of perovskite solar cells is a porous layer of titanium dioxide; a widely used material found in sunscreen and toothpaste. In solar cells the purpose of the titanium dioxide is to allow electrons to travel in only one direction.

A/Prof. Kylie Catchpole’s and Dr Antonio Tricoli’s research groups at the Australian National University (ANU) use a new process called flame spray pyrolysis to deposit the titanium dioxide onto the underlying glass substrate. This results in a highly porous titanium dioxide coating with a large surface area. The research team used the AMMRF (now Microscopy Australia) at ANU for scanning electron microscopy and elemental analysis to see the structure and composition of each layer of the solar cell.

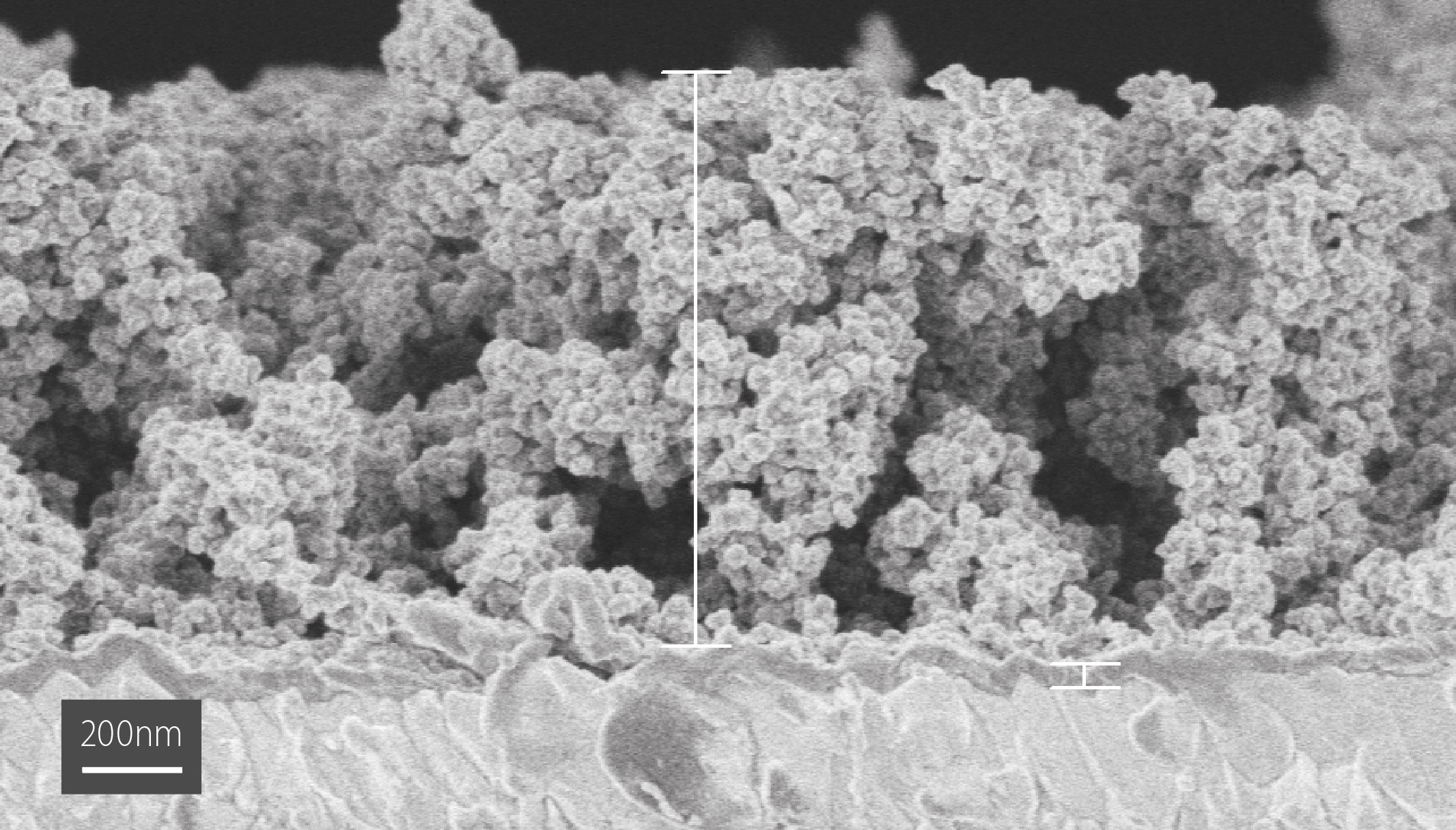

Scanning electron micrograph of titanium dioxide fabricated with flame spray pyrolysis, used for making perovskite solar cells.

Energy capture efficiencies of about 14% have been reached with their initial samples. This is comparable to perovskite cells produced with the standard process. Importantly with the new process, the titanium dioxide layer can be deposited in seconds. This is an important consideration for fabrication on an industrial scale. The success of the flame-spray-pyrolysis process provides a strong base for future work to further optimise the coating process and test it with different materials that may also allow the energy capture efficiency to increase. This will have the potential to make cheaper solar cells that can produce more power for a given area.

Scanning electron micrograph of titanium dioxide fabricated with flame spray pyrolysis, used for making perovskite solar cells.

September 21, 2015