Energy savings in buildings are highly dependent on the materials. While glass is an attractive option on many levels, it is a very poor insulator, transmitting a great deal of heat. Traditional gas-filled double glazing has a number of problems; it requires special framing, has a thick profile, and a limited service life. A more efficient form of insulated glazing would improve the energy efficiency of buildings.

Research started on vacuum-insulating glazing (VIG) technology at the University of Sydney (USyd) over 30 years ago. In the mid 1990s it was licensed to Nippon Sheet Glass (NSG) – now known as the Pilkington/NSG Group. From 2000 the product became commercially available as Pilkington Spacia™, the world’s first commercially available vacuum glazing. It has a thermal conductance approximately one quarter that of a single pane of ordinary glass. Its thermal performance is independent of the size of the space between the two sheets of glass, making the VIG much thinner than existing gas-filled insulating units. This makes it a very versatile technology for the construction industry. The VIG unit is constructed from two panes of glass, maintained at a sub-millimetre separation using an array of high strength metal, ceramic or glass spacers. The two panes are joined around the edges with a rigid bond formed using a uniquely formulated glass frit solder. The space between the panes is evacuated to a very low pressure, and this vacuum gap provides the excellent thermal insulation.

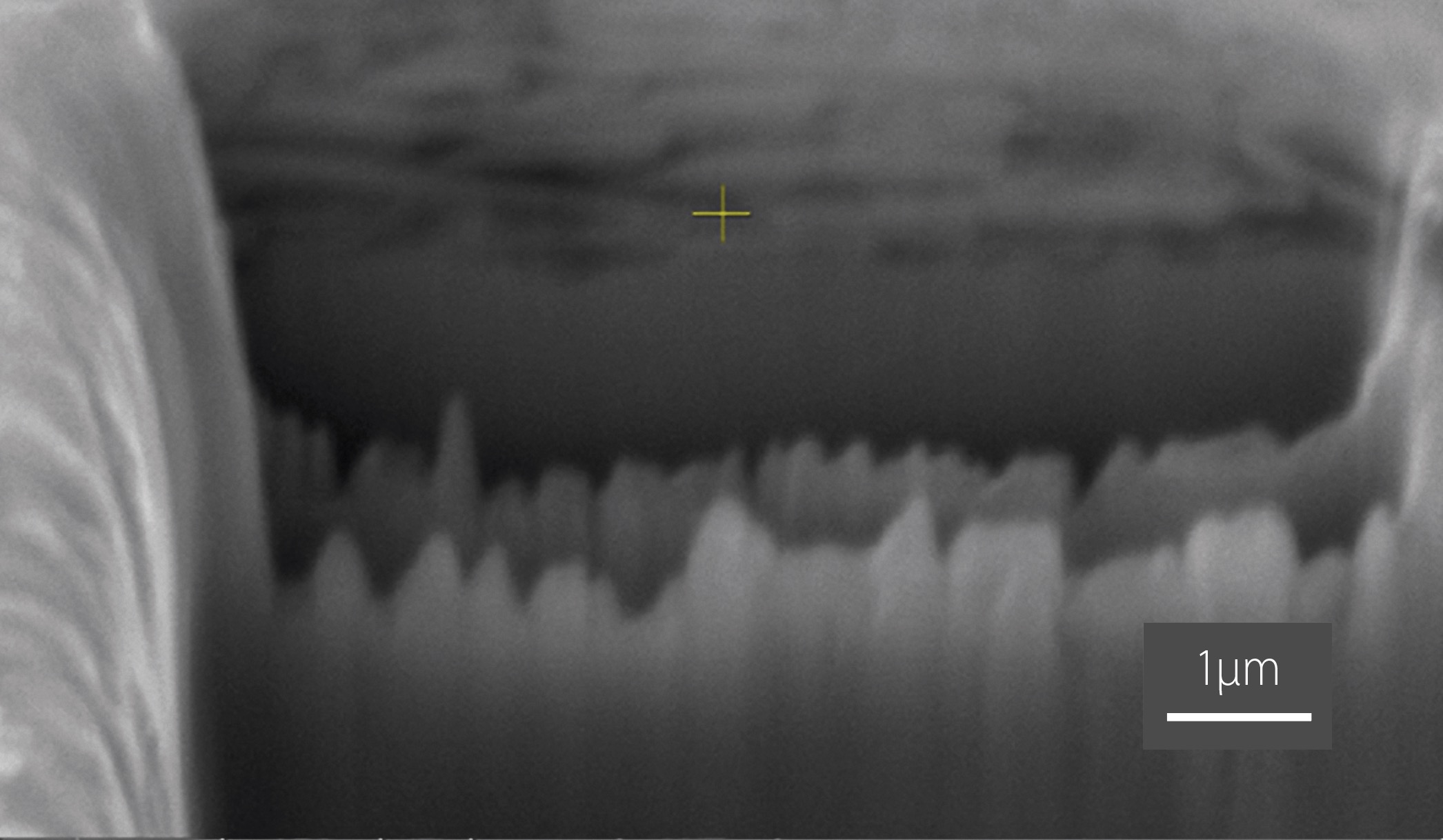

R&D continues through industry partnerships including an ARC Linkage Project, helping USyd test new materials and processes for improvements in the next-generation VIG units. Prof. Marcela Bilek and Dr Cenk Kocer now lead the project, using the AMMRF (now Microscopy Australia) at University of Sydney to look into the composition and structure of VIG materials.

This long-term industry partnership continues to add value to successful commercial products. VIG units provide attractive glazing solutions for commercial, residential and historical buildings, reducing energy consumption and greenhouse gas emissions. Studies have shown that use of insulating windows in Sydney’s climate can make houses comfortable all year round, without additional heating and cooling systems.

The VIG’s lower weight and thin profile:

September 21, 2015