Photolithography transfers patterns onto surfaces using light, usually high-powered laser light. It is widely used to make electronic devices, and modified surfaces for biomedical science, smart materials, and optics applications. However, many photolithographic processes are time consuming, expensive, and require high temperatures. The base materials can also be expensive. In addition, most photolithography is subtractive: once formed it cannot then be easily erased, making rewritable storage difficult. Erasable pattern making is a gap in current processes and could provide new solutions for information storage.

PhD student Samuel Tonkin and Prof. Justin Chalker at Flinders University have recently developed a polymer that can be rapidly and reversibly modified with low-cost, low-power lasers at room temperature.

The serendipitous discovery was made by Dr Christopher Gibson, Director of our University of Adelaide facility, during what he thought would be a routine atomic force microscopy (AFM) analysis session at the Microscopy Australia facility at Flinders University.

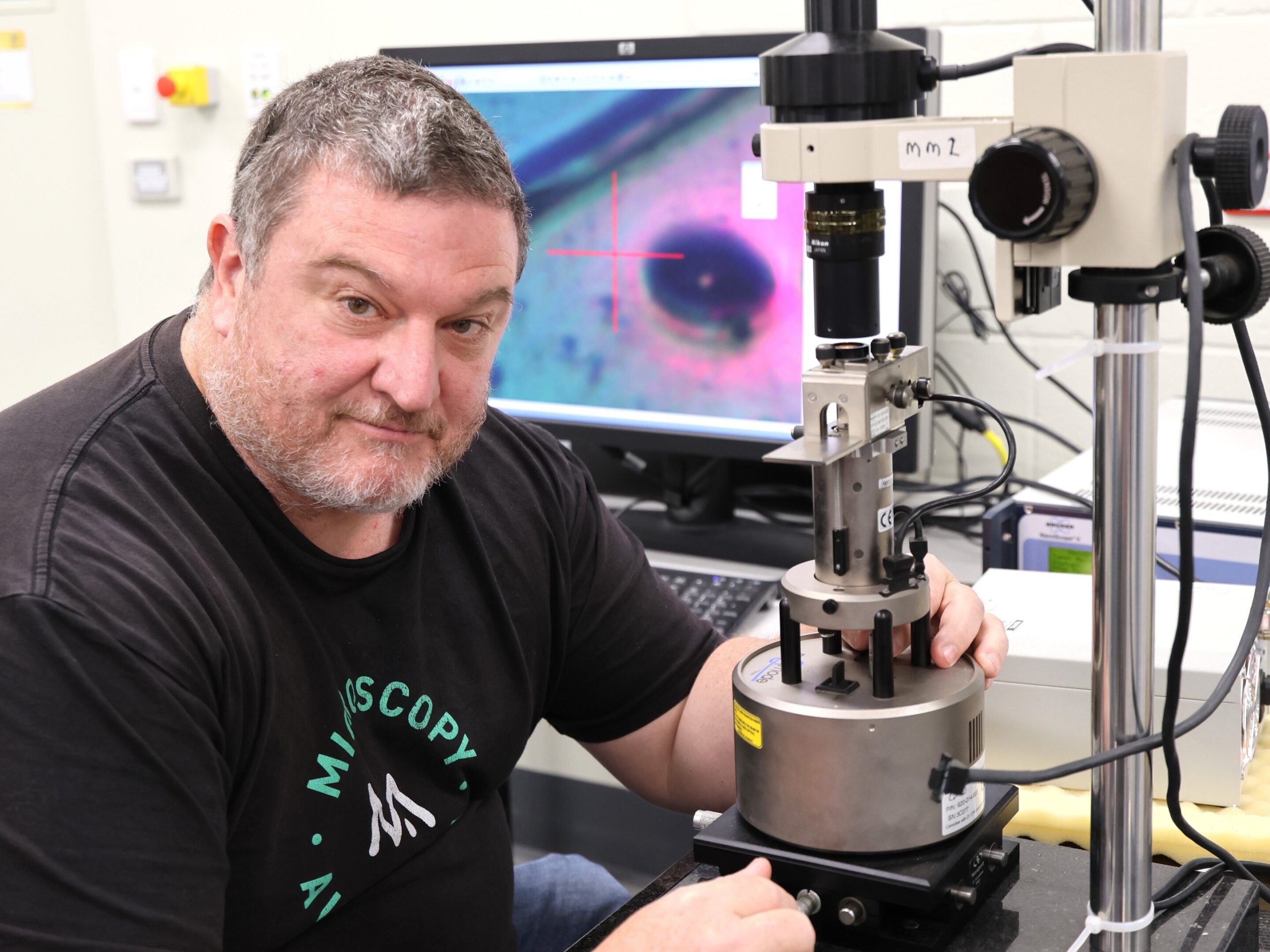

Dr Chris Gibson at the AFM

Dr Gibson explained: “When I exposed the polymer to the low-power laser built into the AFM, the result was a surprise. It was immediately modified, indicating an unusual response not seen when other common polymers are exposed to these lasers. We realised that this phenomenon might be useful in a number of applications, so we built a research project around this discovery.”

By altering the power and wavelength of the laser, the polymer could be precisely modified, generating either swollen or etched regions. They found the swollen regions could be erased with heat. This makes them highly suitable for applications such as direct laser lithography and rewritable information storage systems.

PhD student Abigail Mann and the team have recently explored other ways to use this polymer for rewritable data storage. By using a nanoscale AFM tip to make tiny indents into the polymer, they were able to have a higher density of information, not only in 2D but in 3D, by precisely controlling the depth of the indents. These too can be erased by heat to provide nanoscale, rewritable data storage.

The project team also included Dr Jason Gascooke from the Australian National Fabrication Facility and Dr Lynn Lisboa.

These findings enable a variety of novel applications in rewritable information storage, and direct laser lithography for biomedical, electronics and optics applications. These are rapid, one-step, safe, cheap and easy processes that compare favourably to other methods of lithography that require complex polymer structures, high-power lasers, and multi-step masking, developing and washing protocols.

A. K. Mann et al., Angew. Chem. Int. Ed. 2024, DOI: 10.1002/ange.202404802

A. Mann et al., Advanced Science, 2024, DOI: 10.1002/advs.202409438

Abigail Mann, Jason Gascooke and Lynn Lisboa with their instruments. Image courtesy of Flinders University.

January 29, 2025