Medical and dental implants and devices are central to modern medicine. However, their performance is often compromised by bacterial infections or rejection by the patient’s immune system. Nanoscale structures on the surface of implants are known to affect how the body’s immune system responds, but we don’t yet know much about how it occurs.

In nature there are surfaces that contain a variety of unique nano-structures that make them resistant to bacteria and other microbes. If these nanostructures could be harnessed to inform the design of devices with predictable interactions with microbial and host cells, it could be game changing; creating safer implants and tapping into a multi-billion dollar medical implant market.

Researchers at the University of South Australia led by Prof. Krasimir Vasilev (now at Flinders University) have been striving to replicate natural bacterial and microbial resistant nano-structural surfaces and apply them to titanium orthopaedic and dental implants and trauma devices, from hip and knee joints to catheters. The sharp, spiky nano-surface they have developed mechanically kills the same broad range of bacteria known to cause orthopaedic and dental implant infections, and which can lead to the failure of the procedure. This nanotechnology opens up new ways of preventing infections before they become a serious or potentially life-threatening problem.

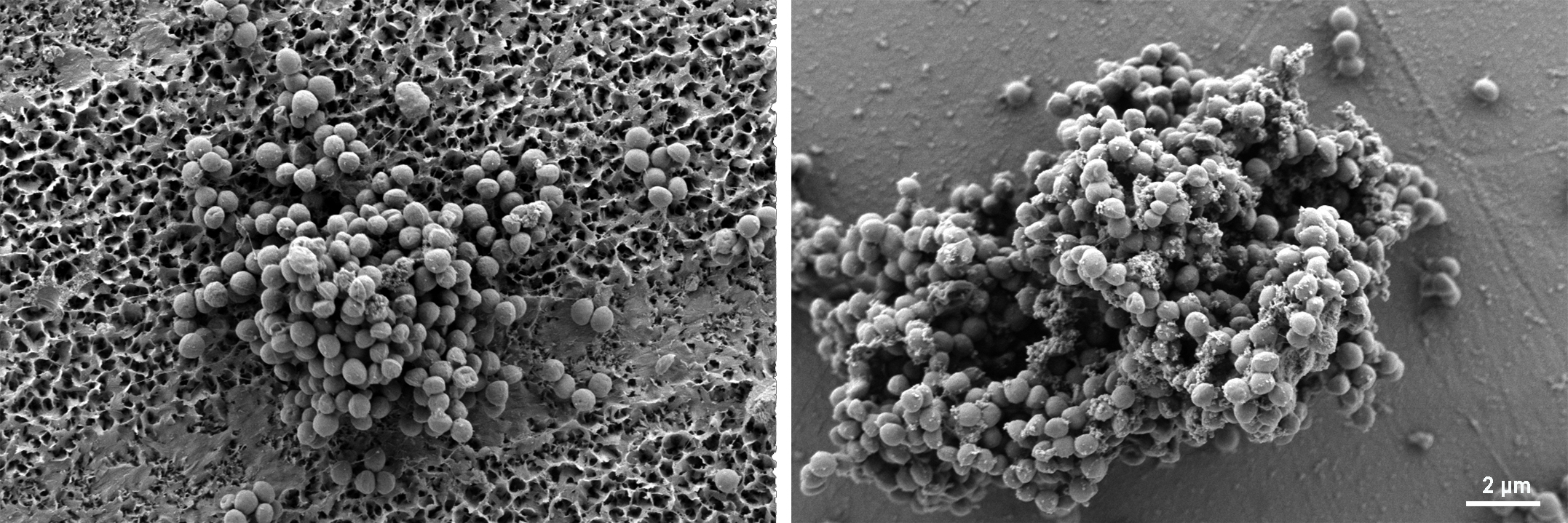

Bacteria growing on flat titanium (right) and on ANISOP’s nanostructured surface (left). This shows that those on the spiky surface are more wrinkled and deflated and are not producing the material (EPS) outside the cells that is responsible for forming dangerous biofims.

Further research by the team revealed that this spiky nanostructure interacts with blood proteins and immune cells to reduce the inflammation response and enhance healing. As well as this, host cells grow as well, or better, on the spiky surfaces than on flat titanium. These structures can therefore create implant surfaces that are both anti-bacterial and anti-inflammatory, providing solutions to two of the key reasons for implant rejection.

Years of ongoing atomic force microscopy, transmission and scanning electron microscopy and confocal microscopy at Microscopy Australia’s University of South Australia, Flinders University and University of Adelaide facilities have made this research possible.

The nano-structural surfaces have been patented in both Australia and the US and have led to the creation of spinout company ANISOP Holdings, which plans to apply the anti-microbial and inflammatory surfaces to advanced titanium dental implants. This will lead to:

“This research started with a clear industry problem and researchers brought their considerable creativity and knowledge to finding a solution that could be applied in an industry context – considering all the elements, from the actual nano-engineering, to how that technology could be brought to a commercial manufacturing environment,” says UniSA DVCR, Prof. Marnie Hughes-Warrington.

Our facilities have also supported earlier research by Prof. Vasilev’s and team into the effect of microstructures on inflammation in the body and the development of plasma coated bandages for chronic wounds that reduce inflammation and infection.

R. M. Visalakshan et al., ACS Appl. Mater. Interfaces 2022 DOI: 10.1021/acsami.2c13415

A. Hayles et al., ACS Appl. Nano Materials 2022 DOI: 10.1021/acsanm.1c04073

April 17, 2023