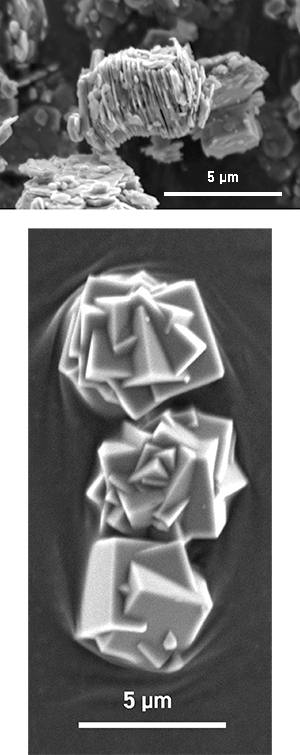

Top image: Kaolin before processing Bottom image: Zeolite produced after processing

Researchers, A/Prof. James Vaughan and Dr Hong (Marco) Peng developed the new, quicker, energy-efficient and greener approach to producing synthetic zeolites. Zeolites are produced from the clay mineral kaolin and play an important role in a cleaner and safer environment. They are an effective substitute for harmful phosphates in powder detergent. Phosphates are banned in many parts of the world because of blue green algae toxicity in waterways. As catalysts zeolites increase process efficiencies, decreasing energy consumption and, as redox catalysts, sorbent zeolites can help remove exhaust gases. Their adsorbent capabilities see them widely used in water treatment, for example, removal of heavy metals produced by nuclear fission.

The technology gives Zeotech a unique commercial edge in capitalising on the kaolin from their Abercorn Project – a large-scale kaolin resource near Monto in central Queensland. The technology also provides a potential commercial remediation solution to the mining industry by using suitable mine and/or process residue streams as a zero-cost feed in the production of high value zeolites. The 2019 global synthetic zeolite market was estimated at USD $5.64 billion.

Synthetic zeolites are commonly known as molecular sieves because of their sponge-like structure and tiny pores. This can be visualised by SEM, which was used extensively during the development of the new process.

The University of Queensland's Dr. Hong Peng, right, who invented the technology being patented to help fast-track Metalsearch's Abercorn kaolin project in Queensland, Australia.

October 23, 2020