Gold is important in many parts of human life and society: not only as a currency and in jewellery but it is critical in electronics, medicine and aerospace technologies. Unfortunately, gold mining has many negative impacts on the environment such as CO2 emissions, deforestation, and the use of highly toxic substances such as cyanide and mercury for gold extraction. Mercury in gold mining is one of the largest sources of mercury pollution on Earth. At the same time, gold-containing e-waste from discarded electronics is a complex but largely untapped resource—one that could be harnessed if safe and efficient recovery methods were available.

An interdisciplinary team from Flinders University, led by Prof. Justin Chalker, has developed a safer and more sustainable approach to extracting and recovering gold, both from ore and, importantly, from e-waste.

Their patented process first uses a low-cost and safe chemical compound to dissolve the gold. This is then isolated by binding it to the team’s unique polymer. The solubilising chemical, called trichloroisocyanuric acid, is currently used in water sanitation and disinfection. When activated by salt water it can dissolve gold and some other metals. Once dissolved and bound to the unique sulfur-rich polymer beads developed by the Flinders team, the polymer–gold complex can be filtered out of the solution. The gold is then released by triggering the polymer to ‘un-make’ itself back to the monomers, which can then be reused.

The team demonstrated that this integrated method delivers high-yield gold extraction from many sources from printed circuit boards in discarded computers, ore from mines and even the trace gold in scientific waste.

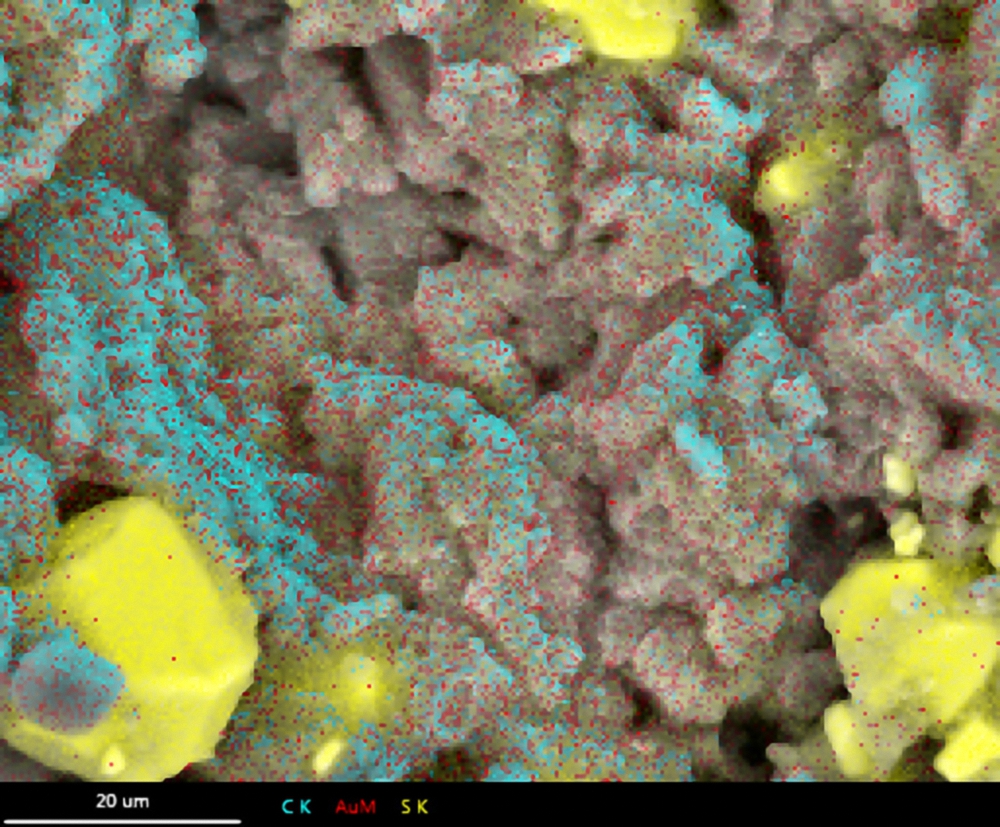

The researchers relied on scanning electron microscopy at our Flinders University facility to visualise the structure of the polymer beads and verify that gold was bound to them. The Australian National Fabrication Facility also contributed to the development of this process.

Scanning electron microscope image of the sulfur-based polymer showing bound gold (red). Sulfur shows as yellow and carbon as blue.

The team collaborated with a team from the US and Peru to successfully demonstrate that this method would support small-scale mines that would otherwise rely on toxic methods to extract the gold, with the associated potential risks to wildlife and the broader environment.

The team plan to work with mining and e-waste recycling operations to trial the method on a larger scale to:

• enable a sustainable value-add for the huge e-waste stream

• provide alternative gold recovery methods that are safer than mercury or cyanide.

• provide new manufacturing opportunities and jobs

• support the many uses of gold, while lessening the impact on the environment and human health.

M. Mann et al., Nature Sustainability 2025

DOI: 10.1038/s41893-025-01586-w

July 23, 2025