Hydrogen itself is a clean fuel but current production technologies are significant producers of carbon pollution. It has great potential as a low-carbon energy source for electricity, heating, hydrogen vehicles and long-distance energy transport. Once burnt, it’s only by-product is water. However, until it can be produced cleanly, it will not be a viable green alternative to fossil fuels.

The HAZER® Process, developed at the University of Western Australia by Prof. Hui Tong Chua, splits methane into hydrogen and graphite using iron ore as a catalyst. This turns methane, a significant greenhouse gas and abundant natural resource, into hydrogen, a source of clean energy. The graphite is also a valuable industrial commodity.

Advanced microscopy by A/Prof. Martin Saunders allowed the cracking process, and the nanomaterials it produced, to be understood. The HAZER® Process produces economically competitive hydrogen with at least 50% fewer emissions than alternative fossil fuel-based hydrogen production.

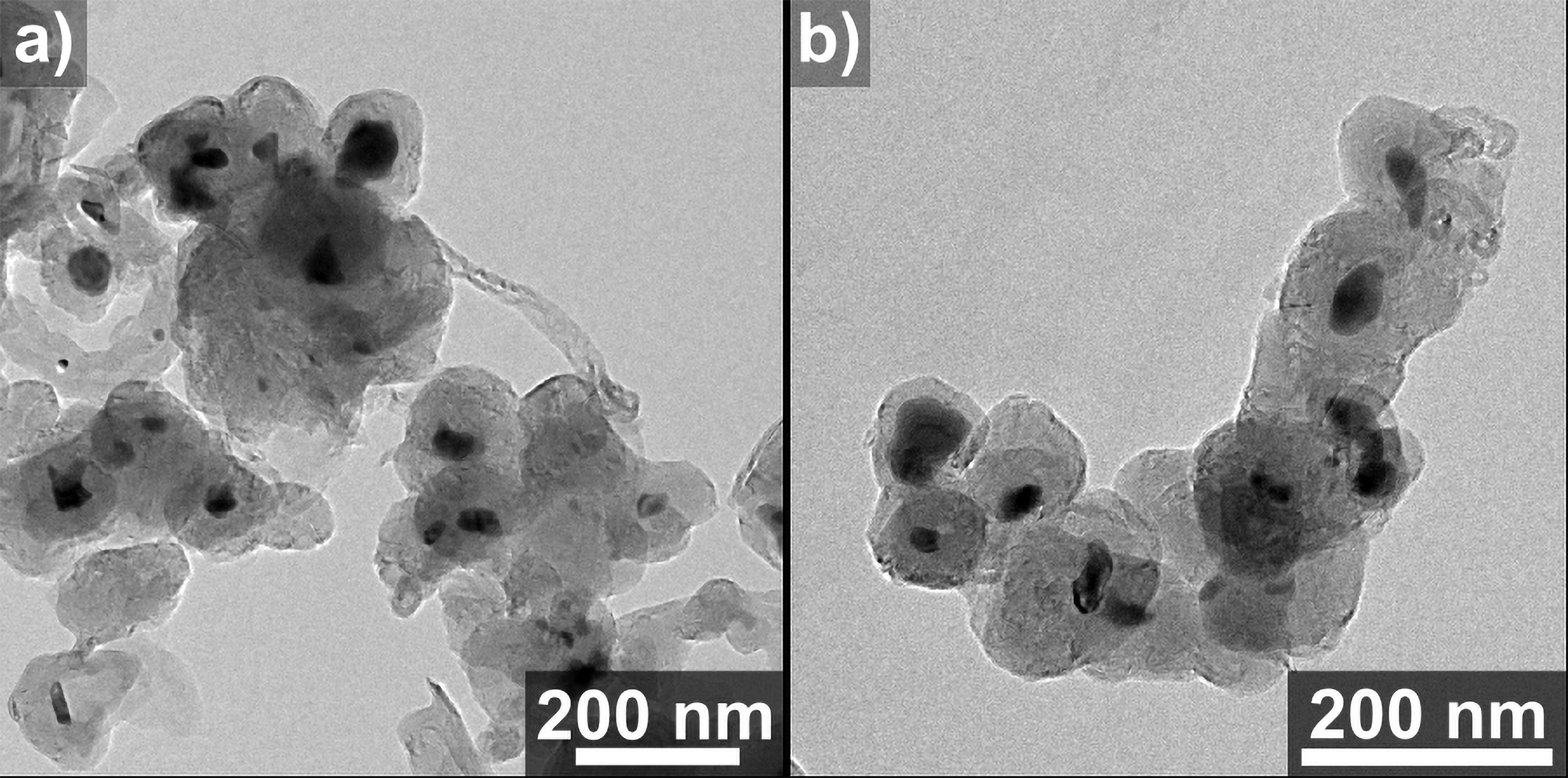

TEM image of carbon nano-onions encapsulating catalyst particles by A/Prof. Martin Saunders

The nano-structured graphite forms as self-encapsulating carbon spheres called carbon nano-onions. These don’t contribute to atmospheric carbon and can be used in everything from hydrogen fuel cells to environmental remediation, capacitors, lithium-ion batteries and much more. The graphite also shows promise for biomedical applications.

“It is heartening that UWA technology is assisting with the Australian economy, especially in the renewable energy sector, in terms of generating employment and building resilience toward a low-emission future” said Prof. Chua.

HAZER® Group is formed to commercialise the economically competitive HAZER Process and take advantage of a global market worth over US$115 billion

Launched on the ASX and received funding to develop a pilot plant to produce ultra-high-purity graphite in Kwinana, WA

Ongoing R&D investigating the use of graphite in applications including Li-ion batteries, water purification, and additives for lubrication products supported by $800,000 grant from IMCRC

BOC Ltd. agrees to supply storage, logistics and refuelling services to deliver hydrogen to end users from a proposed Commercial Demonstration Plant

A successful feasibility study leads to $9.4 million in government funding to support the construction of the HAZER Commercial Demonstration Plant

HAZER team up with the WA state government to turn methane from wastewater treatment into 100 tonnes of fuel-grade hydrogen and 380 tonnes of graphite each year

Hazer Group go international with an MOU with FortisBC and Suncor Energy to develop a hydrogen production facility in Canada called the Burrard Hazer Hydrogen Project – read more here

Man hold a fuel dispenser with hydrogen logo on gas station. h2 combustion engine for emission free ecofriendly transport.

September 22, 2020