Author: Leigh Stephenson, atom probe engineer at Sydney Microscopy and Microanalysis

This exciting instrument is available to everyone through Microscopy Australia’s open access policy, so read on to understand how it can support your research. Its unique features enable access to applications previously unattainable by earlier machines. Why may you care? Well, let me briefly say how in general atom probes work, then an explanation of what makes the Invizo a ground-breaking machine, a measured experience of it so far, and the hopes we have for the machine moving into 2024.

Atom probes are ion projection microscopes wherein a positively biased needle-like specimen (radius < 100 nm) acts as its own electrostatic lens. Surface atoms experience high electric fields (~10–50 V/nm) which further stimulate an ionisation process known as field evaporation. These ions are monoatomic, polyatomic or molecular in nature and, after initial an +1 ionisation, can be ionised again and again before departing the high-field region.

The technique is slowly destructive. The ions are stripped from the surface, one-by-one ideally, and are the imaging media with which the microscope “sees”. They are projected out and away from the specimen along relatively predictable trajectories to be detected by a multichannel plate delay-line detector stack. (If polyatomic or molecular, these ions can dissociate during their flight resulting in complicated trajectories but let’s keep it simple now.) Knowledge of these trajectories form the basis of back-projection algorithms that allow for an ion-by-ion 3D reconstruction of the specimen’s volume. This whole process is driven by voltage or laser pulsing (in addition to a slowly increasing standing bias) which delivers time-of-flight mass spectrometry for the chemical identification of ions.

Modern instruments employ a nearby counter-electrode which focusses the electric field predominantly upon the specimen’s very end and not upon its shank. This relieves the specimen of electrostatic stresses and results in a higher experimental yield. It was that key technical design that has sold so many “local electrode atom probes”. SMM has two of these trademarked LEAPs – a 19-yo LEAP 3000 Si and a 15-yo 4000X Si – and both have had facelifts and upgrades to keep pace with the field and which have been kept in solid working order in recent years by Dr Takanori Sato. These LEAPs employ a once-patented local electrode design of tapered cones with an approximately 40-um through-hole. Experiment success on these machines greatly depends upon the specimen-hole alignment and if the specimen catastrophically explodes (as often can happen particularly with brittle samples) this can damage the nearby local electrode.

The Invizo 6000 employs a new electrode configuration – a flat counter electrode with a comparatively large hole. It intensifies the field to a somewhat lesser degree, requiring a higher bias to achieve the necessary field for ionisation, but otherwise it has advantages over the local electrode. Invizo’s computer vision routines automatically align a specimen to the electrode’s centre which both aides in reproducibility and eliminates any physical stresses caused by manual alignments which lead to specimen failure. And if the specimen does flash-bang-zot the electrode, not being a “local electrode”, is not easily damaged.

The Invizo’s laser pulsing system is innovative if not yet entirely bug-free. In comparison with the 4000’s 355-nm laser, Invizo uses a “deep UV” 257.5 nm laser which generally should provide a more localised surface heating. Additionally, the beam is split into two oppositional directions to achieve even illumination and heating. There is more complexity to the laser focusing but once achieved it seems to require less correction over the course of an experiment. Both laser innovations are intended to widen the applications for atom probe tomography and to provide better yields for projects finding limited success on other instruments.

The system boasts a so-called double Einzel lens technology which does apparently help with the mass-resolving power (MRP) but an improved MRP may also occur by the laser system modifications. Currently, information on this subject is protected but perhaps something like this feature was actually explored in old machines (SMM’s 3000 Si has the latent hardware described as “post-acceleration”) so what is old is new again and maybe that is to the researcher’s benefit.

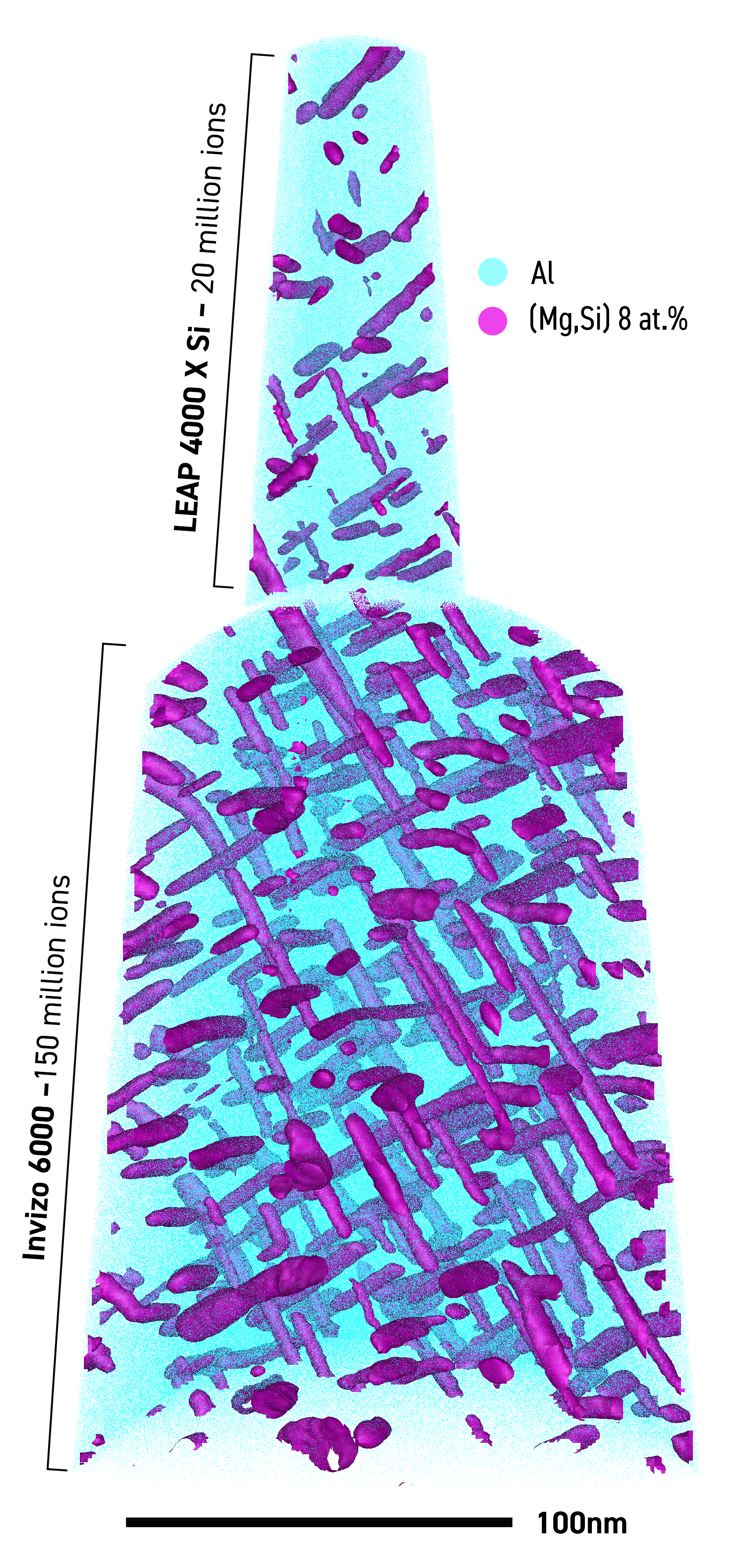

The Invizo 6000 enables a volume reconstruction four times larger than what was previously attainable with other state-of-the-art machines. L. Tegg et al., 2023 Ultramicroscopy DOI: 10.1016/j.ultramic.2023.113826.

Of more significance to the ion optics, and what is more obvious in its impact, is an extraction grid. The drawbacks to this are slightly diminished spatial resolution and a knock on the quantum detection efficiency (~61% with grid down from 81% without). But the grid focuses the field evaporated ions from a wider field-of-view and permits a volume reconstruction four times larger than what was previously attainable with other state-of-the-art machines. This is shown in a direct comparison on an Al-Mg alloy by Dr. Levi Tegg in his recent publication (https://doi.org/10.1016/j.ultramic.2023.113826), see included figure.

The local electrode configuration of the LEAP machines allows for multiple samples to be loaded and run. This is not necessary for the Invizo where only one sample may be loaded at a time. When disappointment is expected, it was an atom probe researcher’s practice to prepare many samples for upcoming disappointment but… the experience is…

My review is “it’s not bad”. The LEAP4000 X Si is still producing quality data which many users may prefer depending upon the questions that they want answered, but the Invizo opens up many exciting applications which were found impossible on other machines like the 4000. Since commissioning, it has been used to analyses vast volumes of additive manufactured nickel superalloys, brittle zirconium alloys, high carbide steels, novel copper alloys, bones and space stones. Its gentle UV laser and direct mode of operation allows analysis of what is often missed – the first layers of a sample – allowing for the analysis of films and oxides upon a specimen.

That is really up to the researcher. If there is an application which has previously failed on earlier atom probes then try it on the Invizo 6000. And did I forget to say (I did) that the Invizo is part of our cryo-suite wherein a cryo-cooled vacuum suitcase can ferry environmentally sensitive samples from our nitrogen glovebox or thermochemical gas-reaction chamber, through our cryostage-equipped plasma FIB for sample preparation, directly into the Invizo for nanoscale analysis of a pristine transient state. With a bit of scientific creativity, it also may be possible to reliably run organics in the atom probe pretty soon.

Which is pretty cool if you ask me.

The CAMECA Invizo 6000. From Left to right: Pierre-Yves Corre, Prof. Simon Ringer, A/Prof. Filip Braet, Prof. Julie Cairney, Dr Takanori Sato, Timothy Kaltenbach, Prasanth Raju, Dr Andrew Breen. Credit Graynoise.

February 19, 2024