X-rays are being used in increasingly varied applications, creating demand for a variety of smaller, portable, higher resolution, high throughput devices. These include machines for medical and inspection techniques, such as radiotherapy, CT scans, breast cancer screening, security inspection and high throughput manufacturing.

Micro-X Ltd has developed and patented an innovative electronic X-ray tube, using carbon nanotubes to miniaturise the X-ray generation components. Developed in collaboration with researchers from Flinders University and the University of Adelaide, with help from a grant from the Department of Innovation, Science, and Technology, this X-ray tube is the key to reducing size, weight, heat and power to produce truly portable X-ray machines. Their proprietary carbon nanotube emitter is now manufactured in Adelaide and forms the basis for all Micro-X’s X-ray products.

Microscopy Australia’s Flinders University facility played a key role in the development of these carbon nanotubes and continues to support the advancement of Micro-X’s systems and manufacturing processes. Micro-X has also benefited from the expertise and infrastructure of another NCRIS initiative, the Australian National Fabrication Facility.

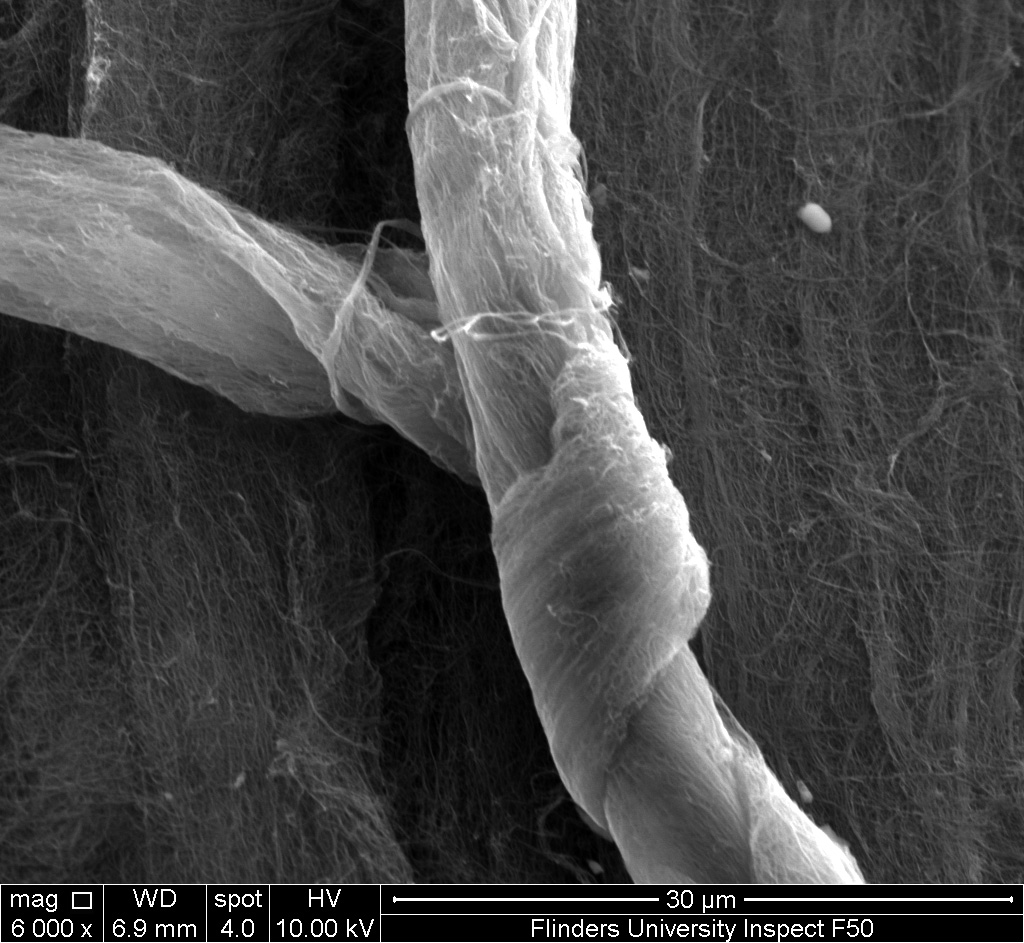

A scanning electron micrograph of Micro-X’s carbon nanotubes, key to their miniaturised X-ray technology, taken at Microscopy Australia’s Flinders University Facility.

This breakthrough technology developed by Micro-X is not only a triumph of Australian innovation but also a catalyst for real-world change. By transforming bulky X-ray machines into lightweight, portable devices, Micro-X is enabling faster, more accessible imaging across healthcare, defence, and security sectors. From hospital wards to disaster zones and airport checkpoints, this homegrown technology is delivering tangible benefits—improving patient outcomes, enhancing national security, and strengthening local manufacturing.

The following achievements highlight the far-reaching impact of this next-generation X-ray innovation:

The establishment of a manufacturing facility in Adelaide that provides substantial benefits in reduced costs, reduced cycle time, improved quality, increased scalability and independence in the global supply chain. In addition, Micro-X has committed to developing, sourcing and manufacturing components locally, supporting Australian manufacturing and creating jobs in South Australia, with over 85% components for the DRX-Revolution Nano domestically sourced.

Micro-X designed and now manufactures the DRX-Revolution Nano for Carestream Health, which won a 2018 Good Design Award. Nano is now installed in an increasing number of Australian and international hospitals. Production was increased in response to COVID-19.

Micro-X has completed two contracts with the Australian Defence Force for a mobile backscatter imager to detect IEDs and an ultra-lightweight, digital, mobile X-ray unit for deployed military medical facilities, with potential applications in humanitarian aid and disaster relief.

Micro-X has completed one and is operating a second contract with the UK Department for Transport’s Future Aviation Security team to develop an imager to detect small amounts of explosive materials concealed in electronics within passengers’ carry-on luggage.

In conjunction with the Australian Stroke Alliance, Micro-X has also produced preliminary designs for a brain CT device that can be mounted into road and air ambulances to diagnose stroke victims before transfer to hospital and a higher resolution 3D breast cancer screening device that doesn’t require breast compression.

Engineers at Micro-X’s Adelaide factory assemble their flagship product, the ‘Carestream DRX Revolution Nano’ X-ray unit.

September 22, 2020