As the lightest metals available for structural engineering, magnesium alloys are the focus of much research, and new processing methods continue to be developed. However, improving the plasticity of these alloys is a challenge due to the crystal structure of magnesium.

Dr Suqin Zhu has worked extensively on these alloys and developed a process called high strain-rate rolling (HSRR) that is strikingly effective at producing high quality magnesium alloy sheets that are strong and easy to work. Dr Zhu is now working with Prof. Simon Ringer at the University of Sydney and uses Microscopy Australia instruments to understand, at a microscopic scale, how HSRR increases strength and plasticity.

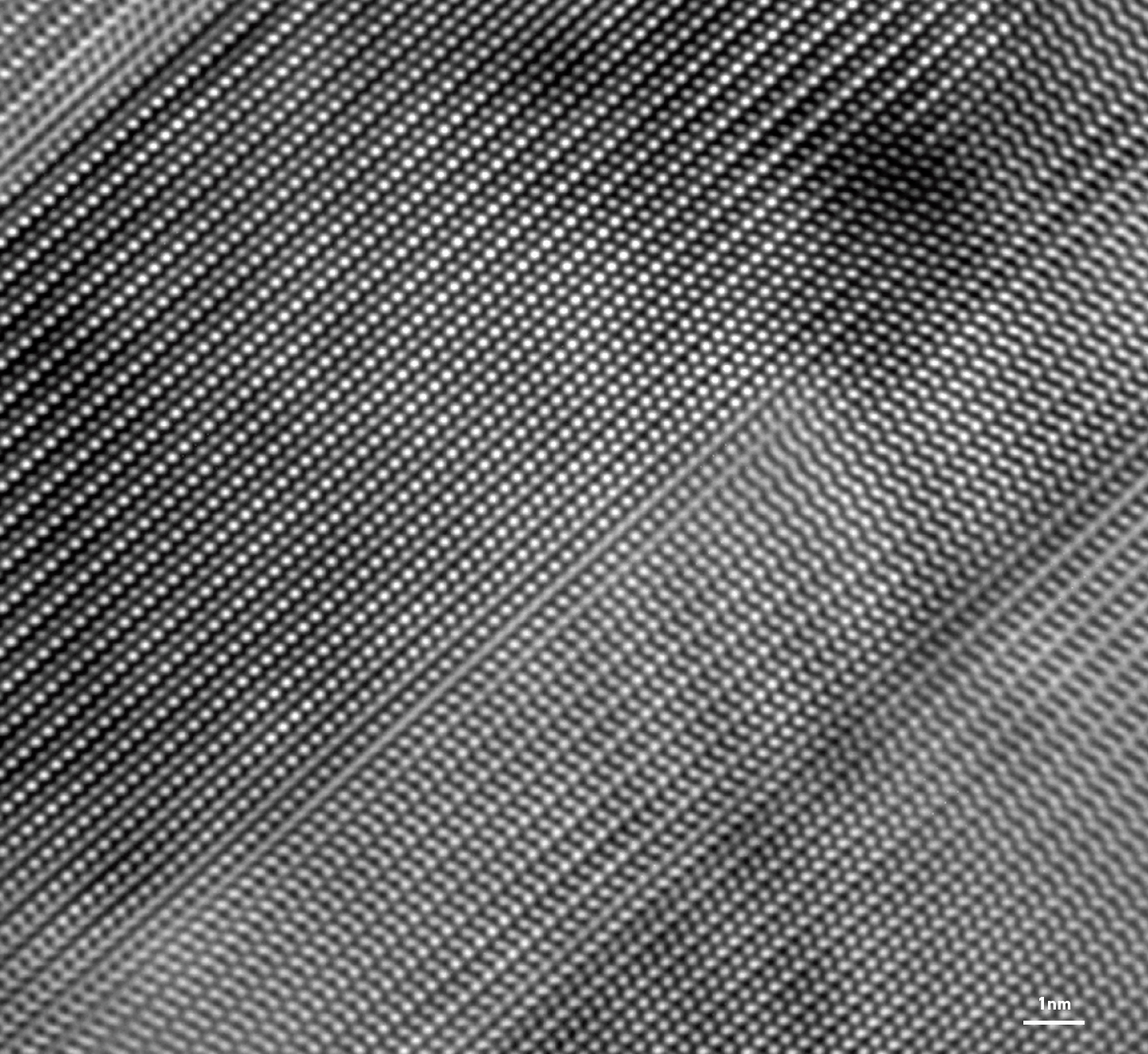

Transmission Kikuchi diffraction and atomic-scale transmission electron microscopy (TEM) revealed that HSRR alloys have a very high density of a particular kind of distortion, known as a stacking fault. These distortions are created in the alloy’s crystal lattice early in the HSRR process. These don’t allow the lattice planes to slide past each other. However, as the process continues at higher strain, these stacking faults transform into a different kind of distortion, known as perfect dislocation, that slides easily.

Atomic scale transmission electron microscope image showing stacking faults and dislocations in a Mg alloy.

Through this series of structural reactions, HSRR makes two significant changes to the structure of the alloy. Firstly, perfect dislocations greatly increase plasticity because they allow the crystal lattice planes to slide. Secondly, HSRR makes smaller crystals, which make the modified alloy stronger and tougher than it was before the HSRR.

Microscopy is essential to the atomic-scale engineering of alloys. If the HSRR process can be scaled to industrial production and commercialised, these innovative magnesium alloys will have great economic potential. They will have applications in vehicles, from trains and planes to cars and bikes, and in electronic and biomedical devices.

TEM image showing stacking faults and dislocations in a Mg alloy.

July 24, 2018