In order to realise the commercial success of these applications, it is important that carbon nanofibre production is scalable to several thousand tonnes per annum, inexpensive and has minimal impact on the environment.

At present, most of carbon nanofibres are produced by chemical vapour deposition using petrol-derived precursors. This production process suffers from high costs, high levels of catalyst residue contaminating the end product, use of hazardous chemicals, difficulty in scale-up, and significant levels of carbon-dioxide emissions.

A/Prof. Takuya Tsuzuki’s group at the Australian National University (ANU) has been working towards more sustainable manufacturing process for carbon nanofibres. His group demonstrated that renewable raw materials, such as plant-derived cellulose, can be converted into polymer nanofibres. They use a scalable green mechanochemical process and the pyrolysis of cellulose nanofibres to form the carbon nanofibres.

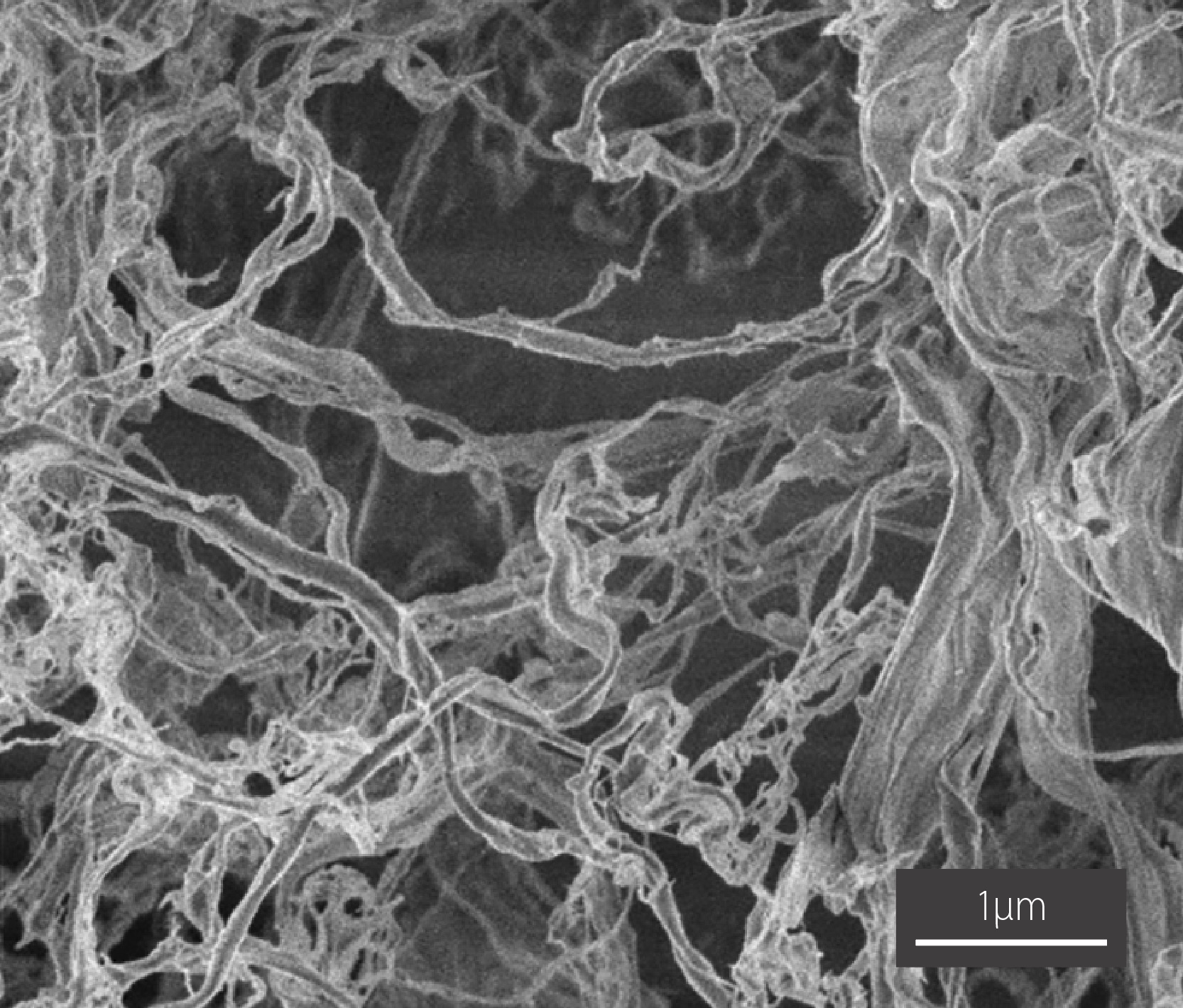

Scanning electron micrographs of carbon nanofibres derived from plant-based cellulose nanofibres.

This study was enabled by the AMMRF (now Microscopy Australia) at ANU, where scanning electron microscopy, transmission electron microscopy and elemental analysis were used to investigate the structure, crystallinity and purity of these ‘green’ carbon nanofibres. The optimisation of eco-friendly, scalable carbon nanofibre production will underpin improvements in lightweight structural composites, solar cell and battery technologies.

November 27, 2016