Australia has a recycling problem. In 2018 when China banned the import of 24 kinds of solid waste, Australia found itself with 619,000 tonnes of recyclable waste a year with no way to process it. Much of this recyclable waste, in particular industrial and e-waste often contains valuable raw materials. However, its heterogenous nature makes it difficult to sort and recycle leading to much of it ending up in landfill. Similarly, tyres contribute a large volume of hard to recycle waste.

Since 2003 ARC Laureate Prof. Veena Sahajwalla, and her team, have used a multitude of techniques at Microscopy Australia’s UNSW Sydney facility, the Electron Microscope Unit, in over 100 publications, to contributing to the development new and innovative ways of creating valuable materials and products from difficult-to-process waste.

Her first major breakthrough was ‘green steel’, which uses waste rubber tyres and plastics as a green replacement for coal during coking in the steel making process.

She then founded the Sustainable Materials Research and Technology (SMaRT) Centre at UNSW Sydney, home of microrecycling science. There modular ‘Microfactorie technologies‘ are being developed to transform problematic waste materials, such as glass, textiles and plastics, into new materials and products, harnessing value from waste resources. These Microfactories are as small as 50-100 square metres and be located wherever waste is stockpiled. The SMaRT Centre is now supporting a number of industry and community-based organisations to adopt this technology.

In addition to her role as Director the new Waste Hub and the Microrecycling Research Hub, Veena is Director of the NSW Government’s Circular Economy Network (NSW Circular).

The SMaRT centre is working on creating valuable products from hard to recycle materials such as:

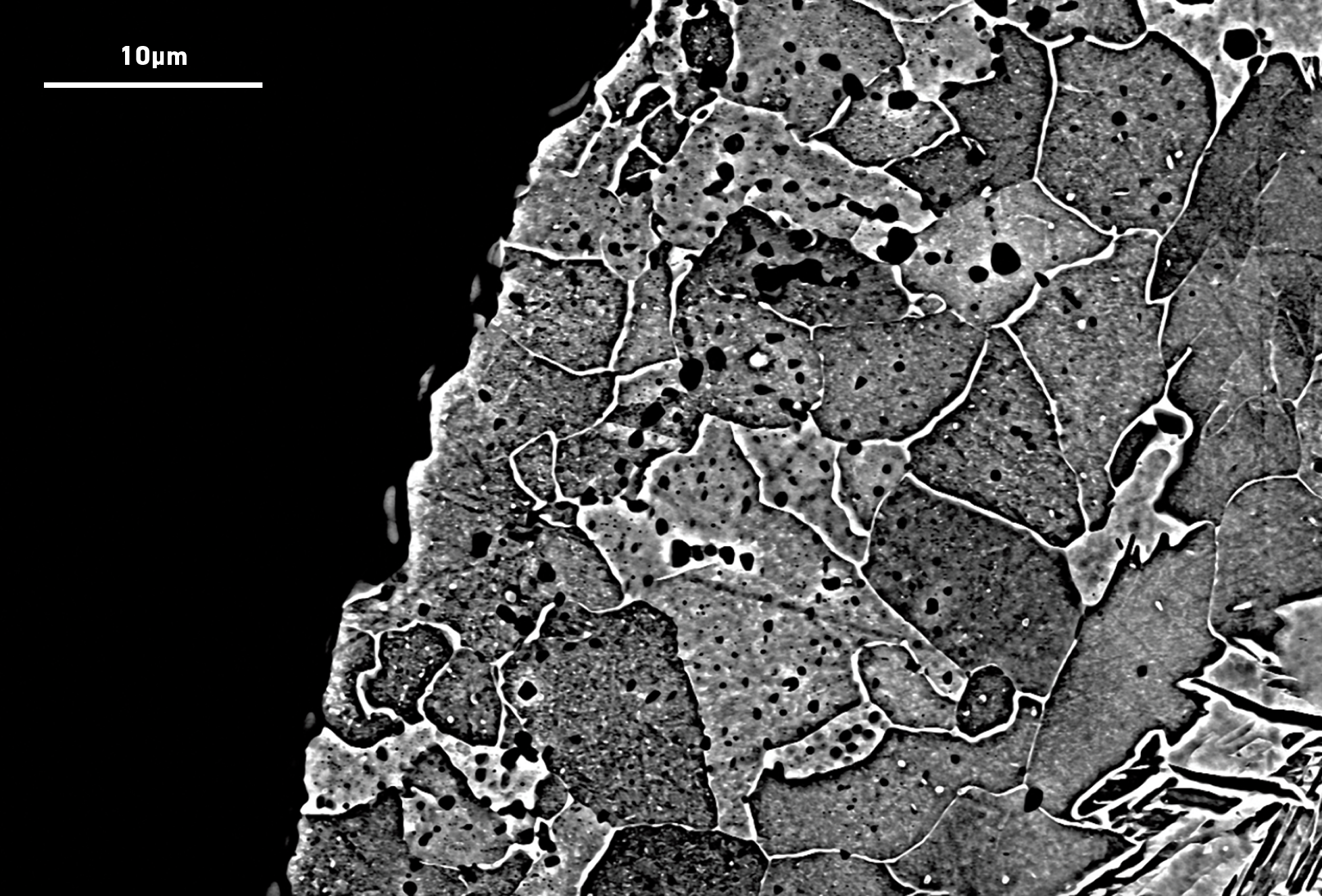

Scanning electron micrograph from our UNSW Sydney facility showing the microstructure of an ultrahard ceramic coating derived from automotive waste.

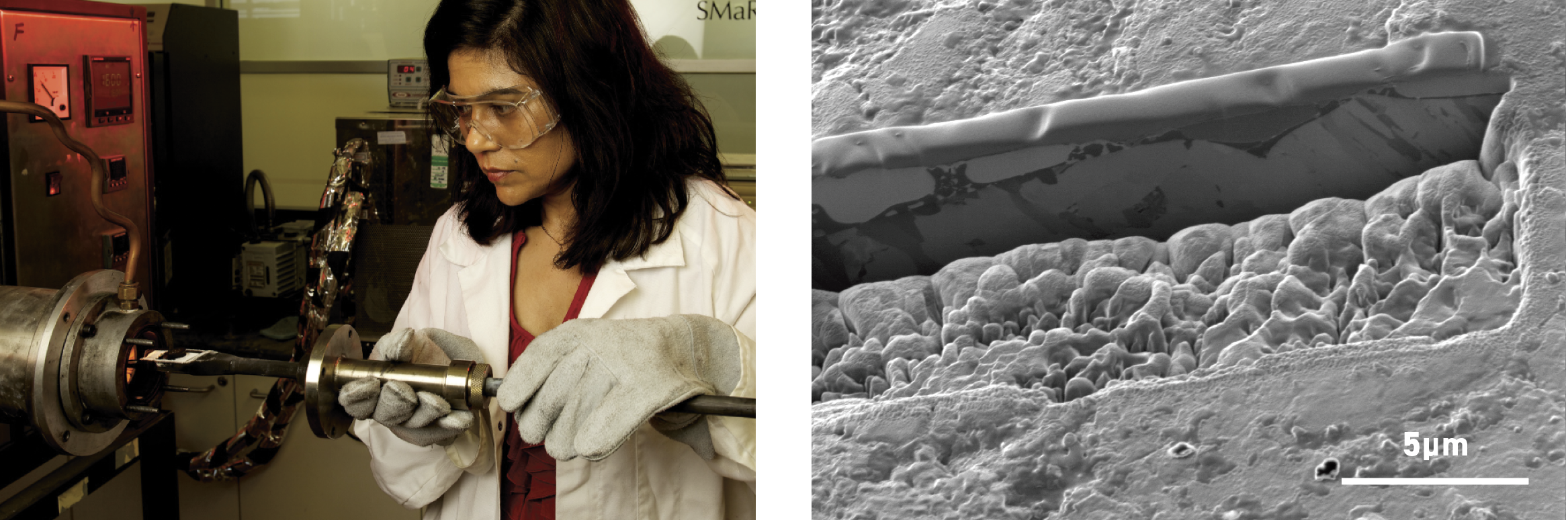

Left: Prof. Sahajwalla at the furnace. Right: The cross-sectional microstructure of the ultrahard surface layer pictured above which has been exposed using a focused ion beam microscope.

The ‘green steel’ technology, has been responsible for millions if tyres being ‘recycled’ for use in steel making, reducing the need for coke and coal. It has been commercialised and is undergoing further R&D with Newcastle-based, global steel maker MolyCop. The process has since been deployed in two domestic and five international sites (in five different countries).

Industry collaborations also include:

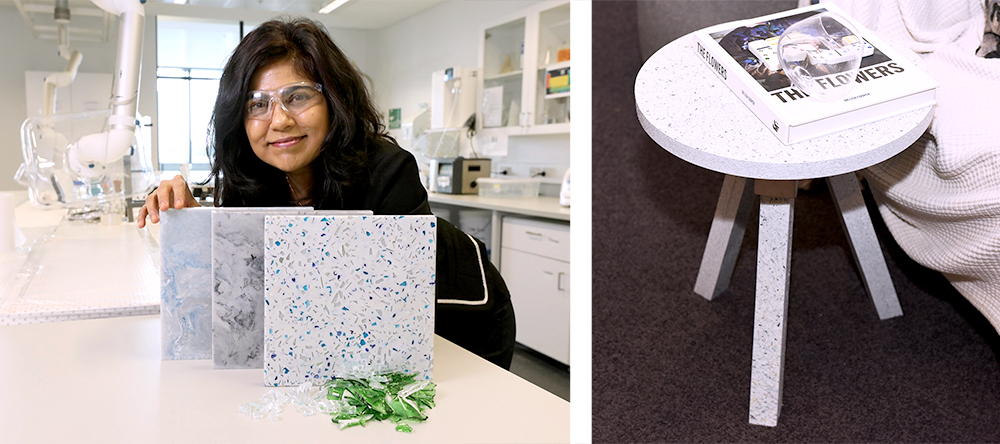

Left: Prof. Sahajwalla with caesarstone like material derived from waste glass. Right: furniture in Mirvac display apartments made from the material.

Prof. Veena Sahajwalla at the UNSW Sydney SMaRT centre. Photo by Anna Kucera.

January 7, 2021