Next-generation, fully stretchable transparent devices will use thin layers of oxide materials completely integrated with elastomeric materials. However, oxide materials are brittle and have processing temperatures often in excess of 300°C. This has prevented their incorporation into stretchable electronic devices.

Mr Philipp Gutruf, working with Dr Sharath Sriram and Dr Madhu Bhaskaran at RMIT University (RMITU), has developed a new method in which the electronics are made on rigid silicon (to withstand the high temperatures) and then transferred in a series of steps onto a flexible substrate. He used scanning electron microscopy (SEM) with a custom-made stretching apparatus at the AMMRF Linked Laboratory at RMITU to investigate device surfaces and image them under stress.

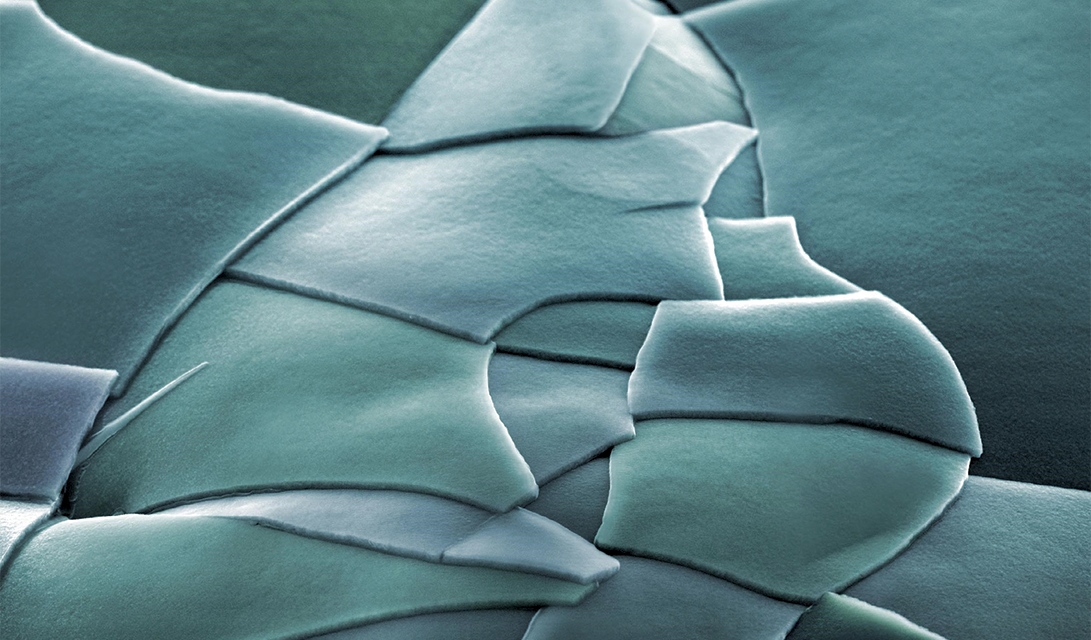

This led to Mr Gutruf discovering the micro-tectonic effect, where microscale plates of the oxide materials are generated through cracking introduced during the fabrication process. The plates slide over each other, very much like geological plates, relieving stress while retaining electrical functionality during stretching. This fortuitous discovery helps to overcome the brittleness of the oxides.

Mr Gutruf found that indium tin oxide, the industry standard for transparent conductors, has a stretchability of up to 15%, making it suitable for wearable devices. This research is a leap forward in realising stretchable transparent electronics.

Gutruf et al., NPG Asia Materials 5, 2013 DOI: 10.1038/am.2013.41

Colour-enhanced SEM of a micro-tectonic surface of indium tin oxide. (image: Linnea Rundgren)

Colour-enhanced SEM of a micro-tectonic surface of indium tin oxide. (image: Linnea Rundgren)

October 23, 2014