Miniscrews are popular because they are relatively cheap, surgically easy to insert, have multiple placement options, and most importantly, don’t depend on patient compliance and unsightly headgear. However, the success rate of TADs is not particularly high with some screws moving or even pulling out altogether.

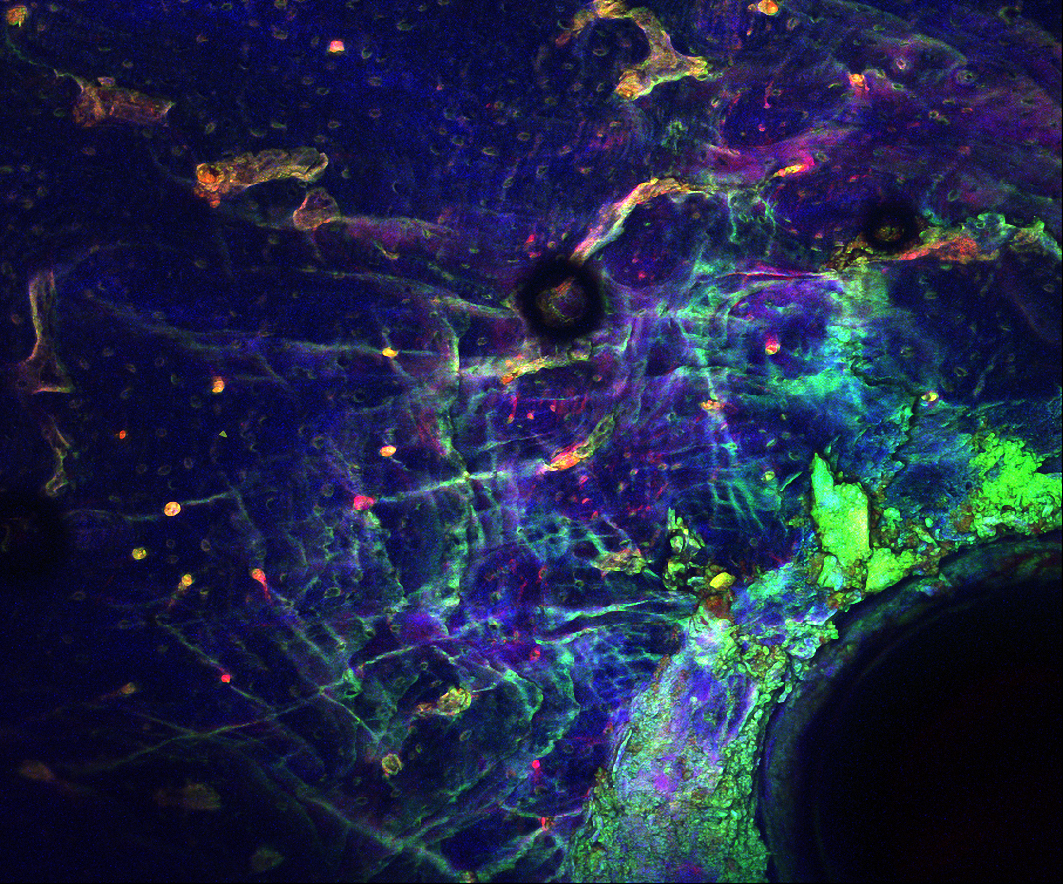

Confocal image showing cracks caused by a 1.5mm diameter TAD on 1mm thick compact bovine bone. Microcracks caused by screw insertion are shown in green and by removal, in blue.

Clinical observations suggest a higher failure rate when the screws are put into areas where the compact bone is thicker. Dentist and postgraduate student Dr Melissa Nguyen at the University of Adelaide (UoA) is studying this at the tissue level by using confocal microscopy in the AMMRF (now Microscopy Australia) at the UoA. Stresses caused by the insertion of screws cause microdamage to the bone in the form of microcracks. This causes the bone to remodel itself around the screws. First, specialised cells remove damaged areas before other cells move in to deposit new bone. The initial removal of the damaged bone is the cause of wobbly screws. Dr Nguyen has found a network of cracks emanating from the screw insertion points and her early results appear consistent with the clinical observations.

By understanding how bone thickness and insertion torque lead to microcracks, orthodontists should be able to position screws more reliably and control the insertion forces, thereby reducing miniscrew failures.

Confocal image showing cracks caused by a 1.5mm diameter TAD on 1mm thick compact bovine bone. Microcracks caused by screw insertion are shown in green and by removal, in blue.

September 21, 2015