In a world in need of cheaper, sustainable and clean energy solutions, solar is an obvious option. 200,000TW of energy from the sun falls on Earth each year, this is 10,000 times more than the total global energy demand. However, the cost and efficiency issues of different solar cell technologies continue to challenge researchers.

Researchers at Flinders University found that including a layer of phosphorene can increase the efficiency of a variety of next-generation solar cell types that are cheaper, more adaptable and easier-to-manufacture. It comes from the ingenious combination of two techniques developed Microscopy Australia’s South Australian facilities – Prof. Joe Shapter’s microwave exfoliation of black phosphorus and Prof. Colin Raston’s vortex fluidic device.

“Silicon is currently the standard for rooftop solar, and other solar panels, but they take a lot of energy to produce them. They are not as sustainable as these newer options,” said adjunct Professor Joe Shapter, who is now at the University of Queensland.

“Phosphorene is an exciting material because it is a good conductor that will absorb visible light. In the past most non-metallic materials would have one property but not both.”

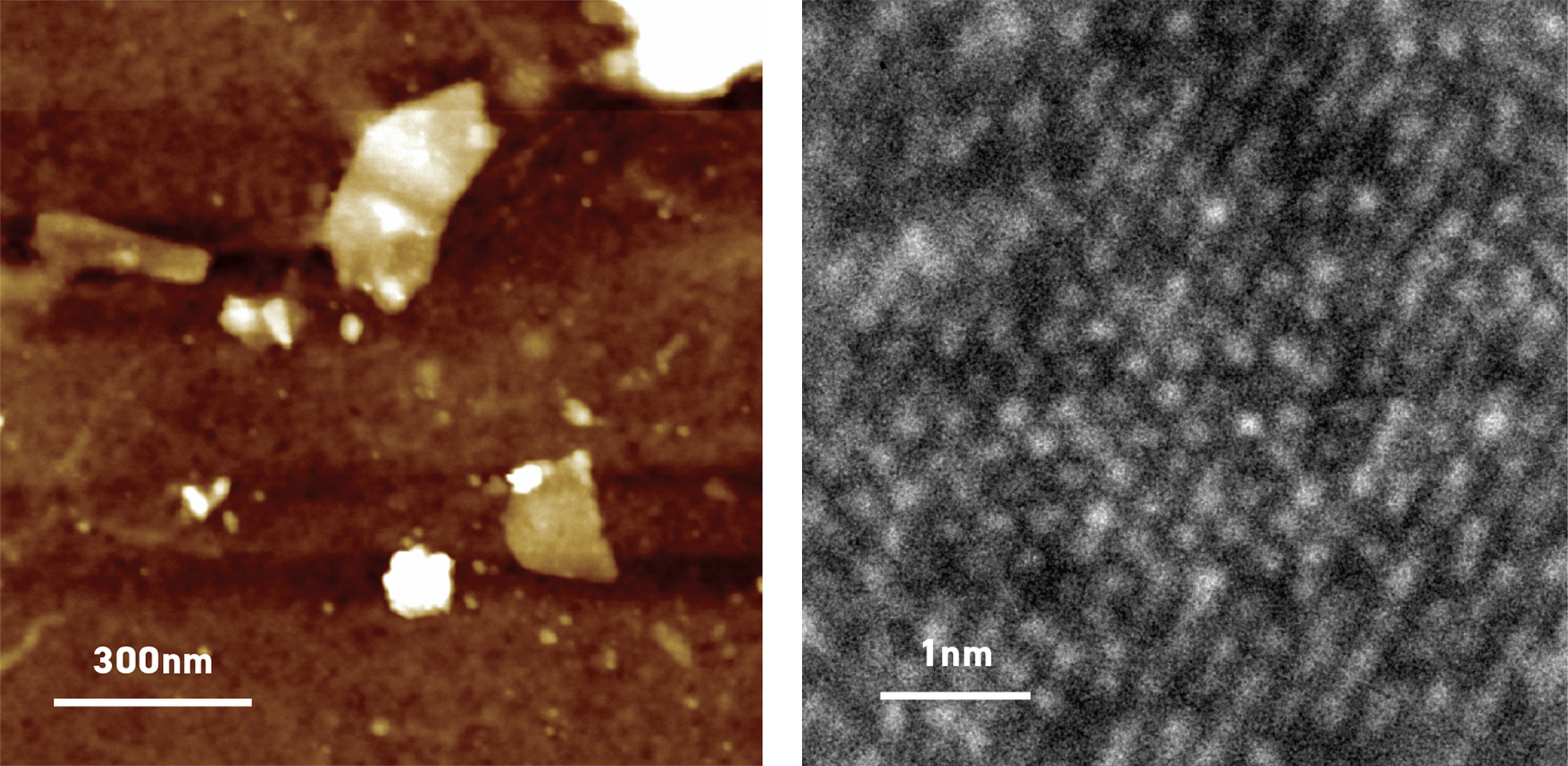

Left: Atomic force microscopy image of a flake of phosphorene. Right: Transmission electron micrograph of atoms in a phosphorene flake. Both taken at Flinders Microscopy and Microanalysis.

In 2017 a team lead Prof. Joe Shapter and Dr Munkhbayar Batmunkh showed that black phosphorus immersed in a common organic solvent and exposed to microwaves for just 10 minutes produced phosphorene flakes. Previously, 15 hours of treatment would have been required. The team used a wide range of techniques, including atomic force, transmission and scanning electron microscopy, at Microscopy Australia’s South Australian facilities to examine the nanoflake structure providing evidence that the novel method produced thinner, higher quality phosphorene flakes.

Dr Christopher Gibson, co-author and atomic force and raman microscopy leader at our Flinders University facility explains below.

They then tested phosphorene as an electrocatalyst in several solar cell types. In dye-sensitised solar cells, which are thin-film, semi-flexible, translucent and simple to make, phosphorene cells showed superior photovoltaic efficiency of 8.31%, outperforming the expensive platinum-based ones. In carbon nanotube–silicon–the use of phosphorene resulted in a 25% improvement in power conversion over the carbon nanotube–silicon alone.

The results of the microwave experiments to produce phosphorene – and its potential application in the solar industry – has been published in leading international chemistry journals Angewandte Chemie, Advanced Function Materials and Small Methods.

Following this, in 2019, the Flinders University team developed a new method for making phosphorene in large quantities, along with other future materials such as graphene, using the vortex fluidic device. This paves the way to sustainable, large scale production of phosphorene, increasing it’s commercial viability. Once again, a large range of microscopy techniques across Microscopy Australia’s South Australian facilities were employed to characterise the flakes. The results were published in Small Methods.

“Our latest experiments have improved the potential of phosphene in solar cells, showing an extra efficiency of 2%-3% in electricity production,” says Dr Christopher Gibson.

The research team is now exploring the potential for phosphorene nano-dots to be used as a cost effective catalyst for producing hydrogen for green energy. They have found that the microwave technology, originally used to split phosphorus into thin layers of phosphorene, could also produce phorphorene nano-dots if treated for a longer period. The results have been published in The Journal of Materials Chemistry A.

Dr. Christopher Gibson, co-author and staff member at Microscopy Australia's Flinders University Facility, Flinders Microscopy and Microanalysis

August 20, 2020