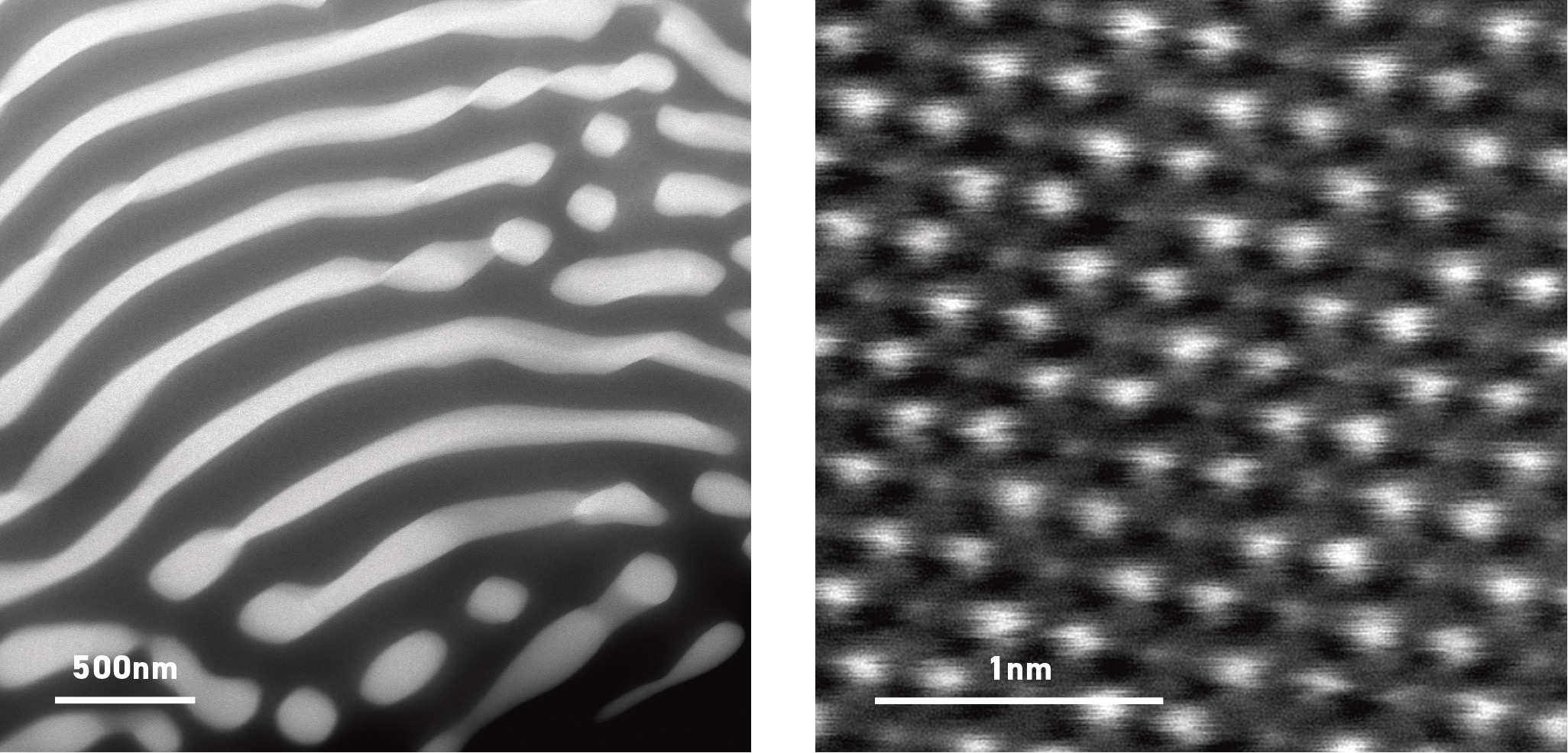

One of these is Dr Yujie Chen at the University of Adelaide (UA). She has developed a micro-structured multi-metal alloy, designed with two phases (the dark and light bands in the image); the dark phase provides good malleability while the white phase gives the material high strength.

Left: TEM image showing the two phases in the alloy

Right: High resolution STEM image of the hexagonal arrangement of atoms in the lighter phase. The atoms show up as lighter dots against a black background.

This combination of properties results in an alloy with extremely high performance, and tuneable properties depending on the microstructure and the materials chosen for the phases. High resolution scanning transmission electron microscopy (STEM) conducted in the Microsopy Australia facility at UA revealed the crystal structure of the stronger (lighter colour in the striped image) phase. It shows that the atoms of two metallic elements are arranged in a hexagonal structure, while the more malleable (darker) phase has another set of metal elements arranged in a face-centred-cubic (FCC) microstructure. Understanding the structure in this way enables the research team to make alterations to incorporate specific properties into their alloys to address particular functional needs.

July 26, 2019