Prof. Michael Yu, Dr Xiaodan Huang and Yueqi Kong from the University of Queensland (UQ) have used graphene to create electrodes for aluminium ion batteries, which are more efficient than lithium ion batteries. The technology was developed using transmission electron microscopy at Microscopy Australia’s UQ facility. It has since been patented and licensed by UniQuest to Brisbane-based Graphene Manufacturing Group (GMG).

GMG will manufacture battery prototypes for watches, phones, laptops, electric vehicles and grid storage under a research agreement with the scientists from UQ’s Australian Institute for Bioengineering and Nanotechnology.

They plan to use local raw materials to manufacture battery cells at a competitive cost to replace imported lithium-ion cells, reducing international supply chain risks and creating local jobs. “We’re excited about developing the commercial prototypes followed by initial production here in Australia – at a location yet to be determined,” said GMG CEO Mr Craig Nicol.

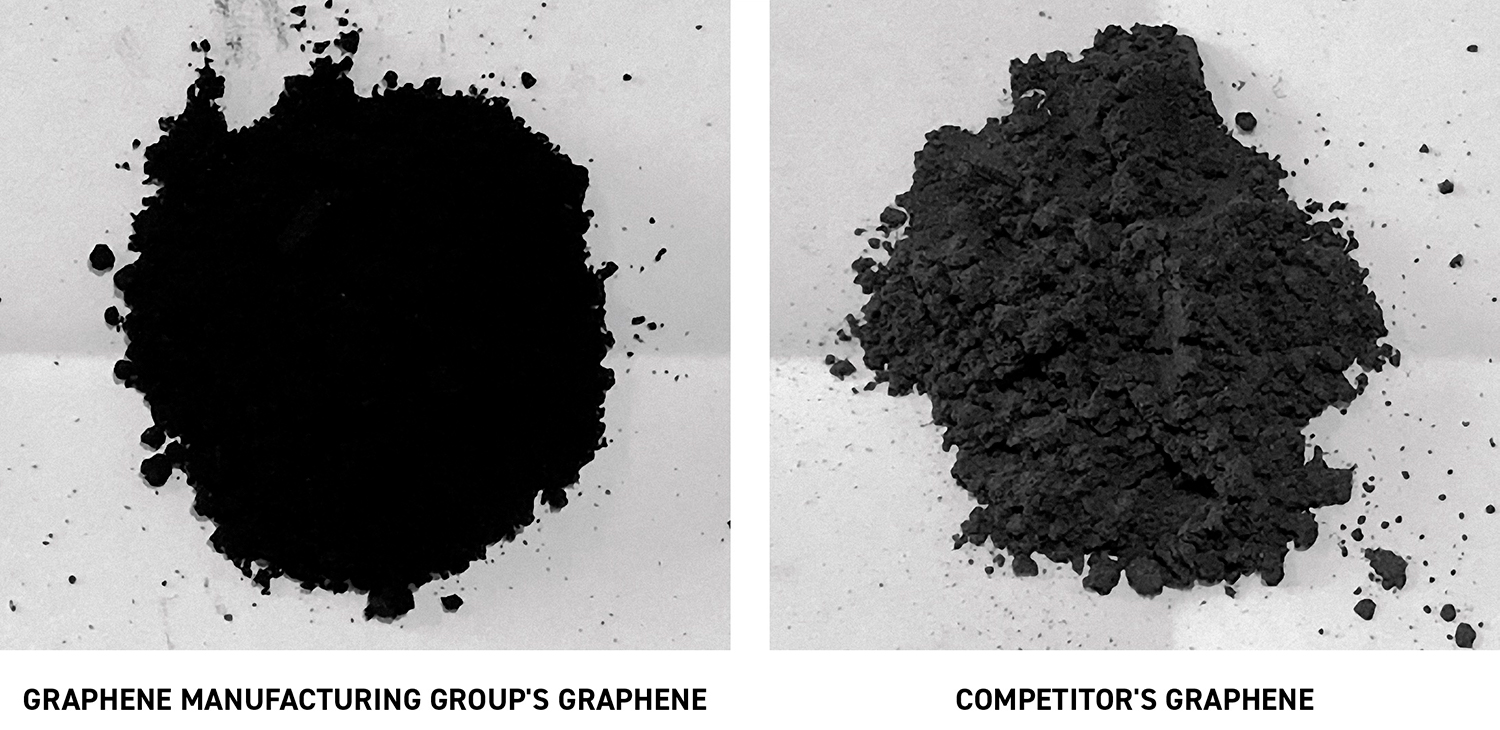

GMG use Microscopy Australia’s electron microscopy facilities at UQ for regular, rapid monitoring of their graphene during production and to tailor it’s properties for different commercial applications. They initially used Microscopy Australia’s University of Sydney facilities as they developed their processes.

“Our innovative production process is world-leading, so it is essential to understand exactly what we are manufacturing. The analysis done for us at Microscopy Australia’s University of Sydney facility has been instrumental in both the process and product design of our graphene. It allows us to streamline improvements before and during production as well as confirming post-production efficacy.

“This enables us to adjust operating windows during our manufacturing process and directly link the characteristics of our graphene with tangible customer outcomes. This independent analysis is also essential for us in building successful relationships with our current and future customers and with our investors.

“We now have confidence to better understand the improvement mechanisms required for multiple applications of the wonderous product we produce,” said GMG CEO Mr Craig Nicol.

GMG is an Australian based clean-tech disruptive company listed on the TSXV (TSXV:GMG) that produces graphene and hydrogen by cracking methane (natural gas) instead of mining graphite. By using the company’s proprietary process, GMG can produce high quality, low cost, scalable, ‘tuneable’ and no/low contaminant graphene – enabling demonstrated cost and environmental improvements in a number of world-scale planet-friendly/clean-tech applications. Using this low input cost source of graphene, the Company is developing value-added products that target the massive energy efficiency and energy storage markets.

UQ’s research team was awarded $390,000 from the Australian Research Council’s Linkage Project in 2020 over three years to develop the graphene aluminium ion technology.

Published 8th June 2021

Transmission electron microscope images of two GMG graphene samples

June 8, 2021