By enabling research around the country, Microscopy Australia contributes directly to seven of those technologies. Some specific examples are given below.

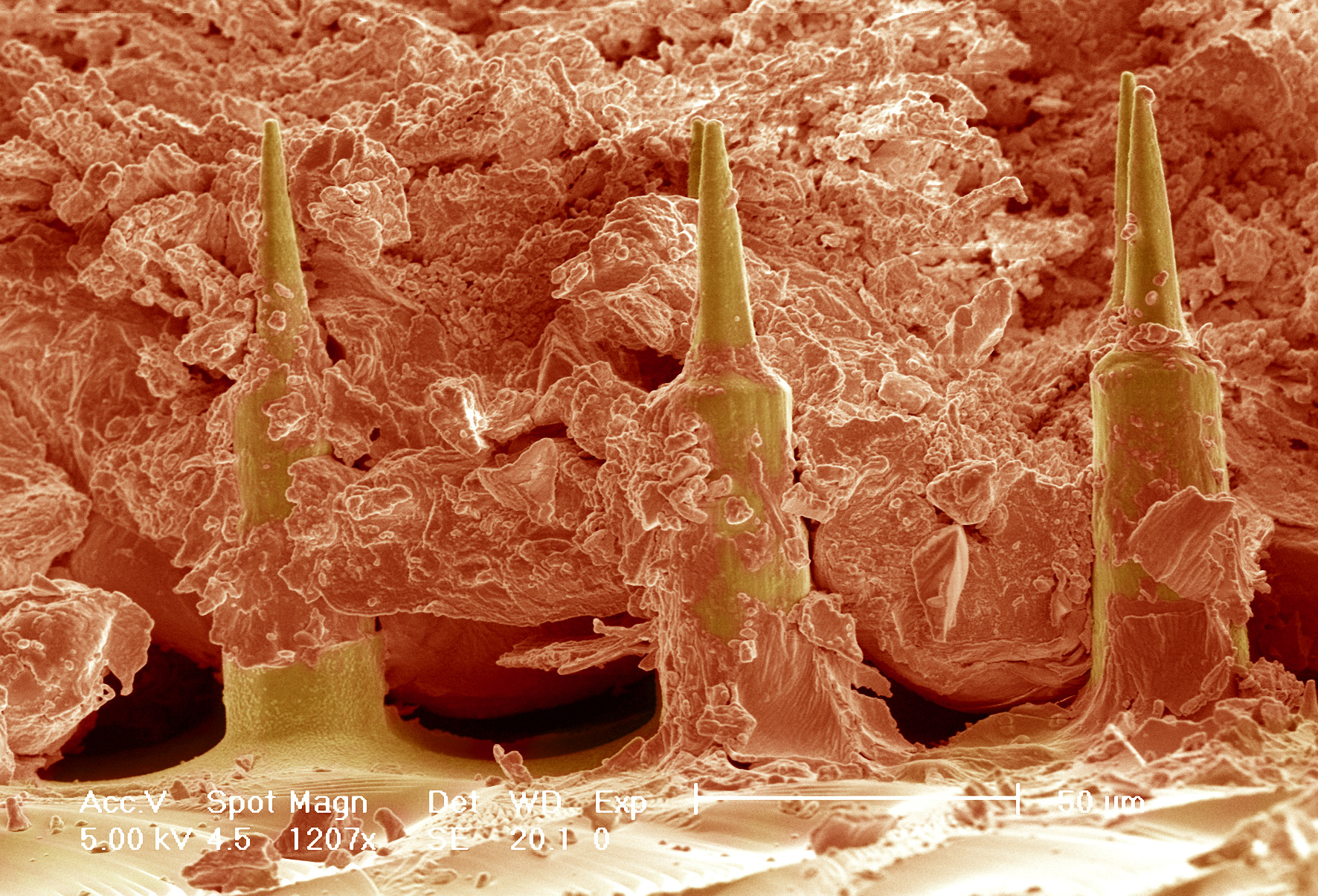

Colour-enhanced scanning electron micrograph of a Nanopatch™ (gold) in skin (brown)

Since the early days of its development, we have provided access to instruments and expertise to support the Nanopatch research team led by Prof. Mark Kendall (now at ANU) and those at Vaxxas who are commercialising this innovative vaccine platform. We have also supported the application of similar technology to the development of sensing devices, now being commercialised through WearOptimo.

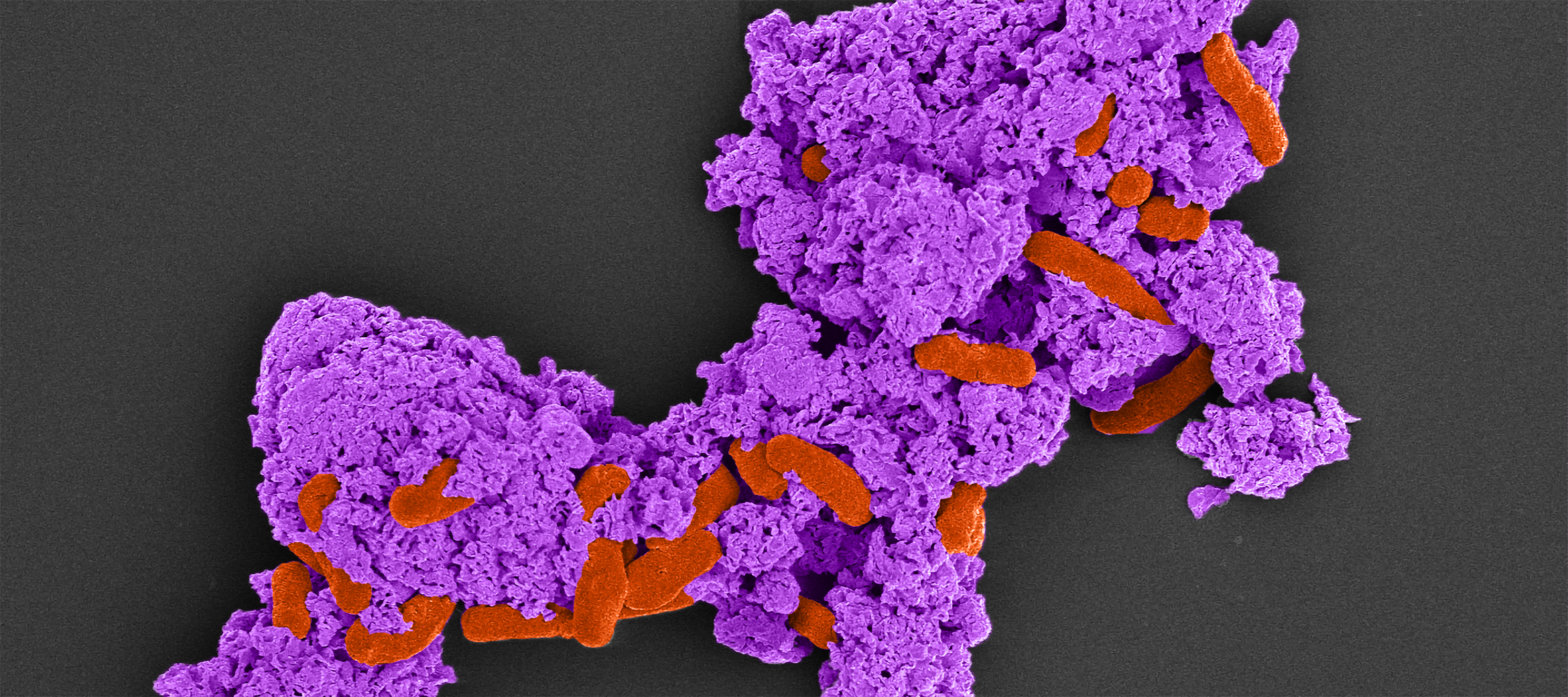

Colour enhanced scanning electron microscope (SEM) image of E. coli (orange) surrounded by polyethylenimine and carbon nitride (purple)

Engineers at Monash University have developed a new solar filtration method to remove deadly bacteria, such as E. coli, from water using graphitic carbon nitride with polyethylenimine – a safe and low-cost material that doesn’t leach metals back into the water to create secondary pollution.

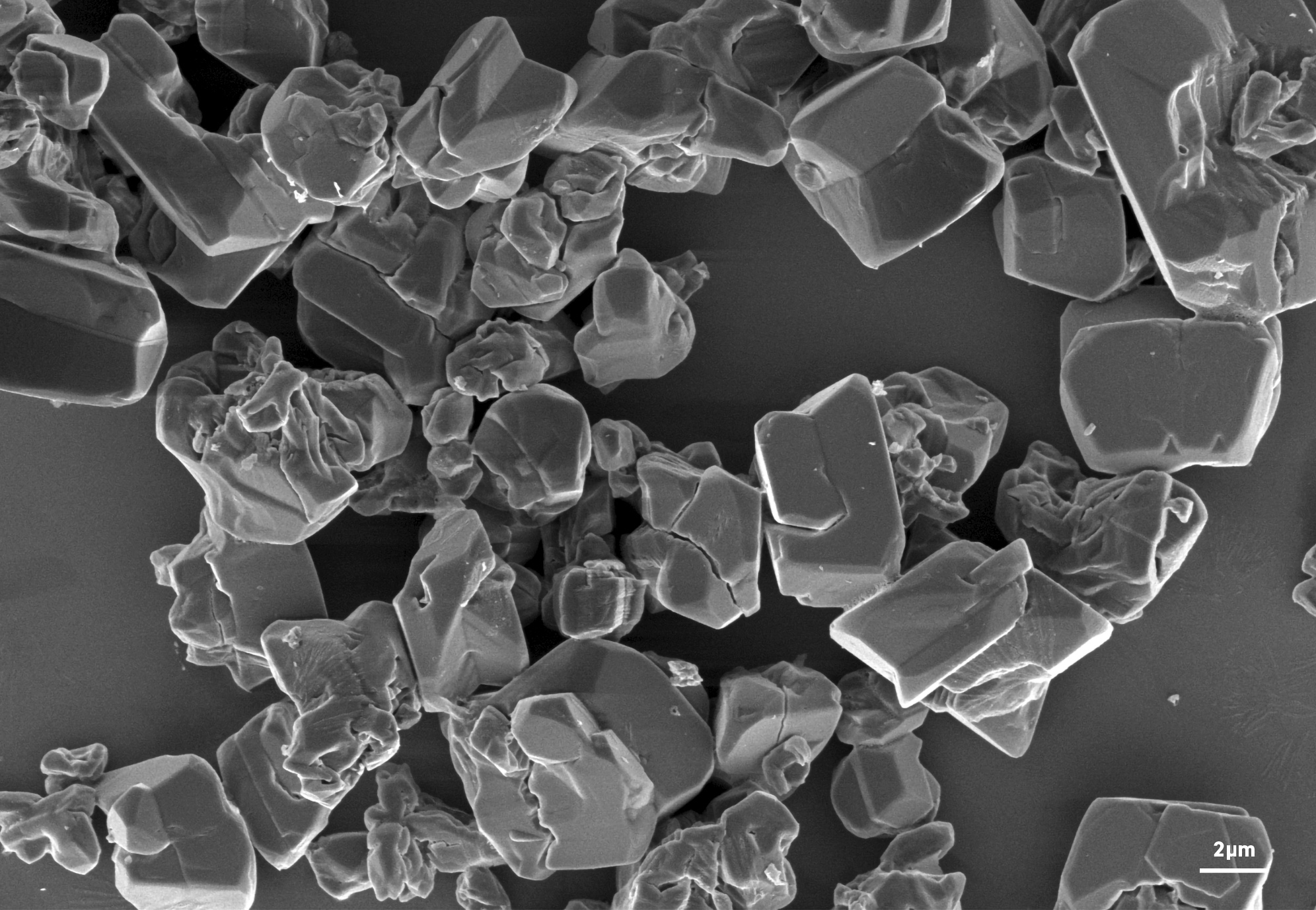

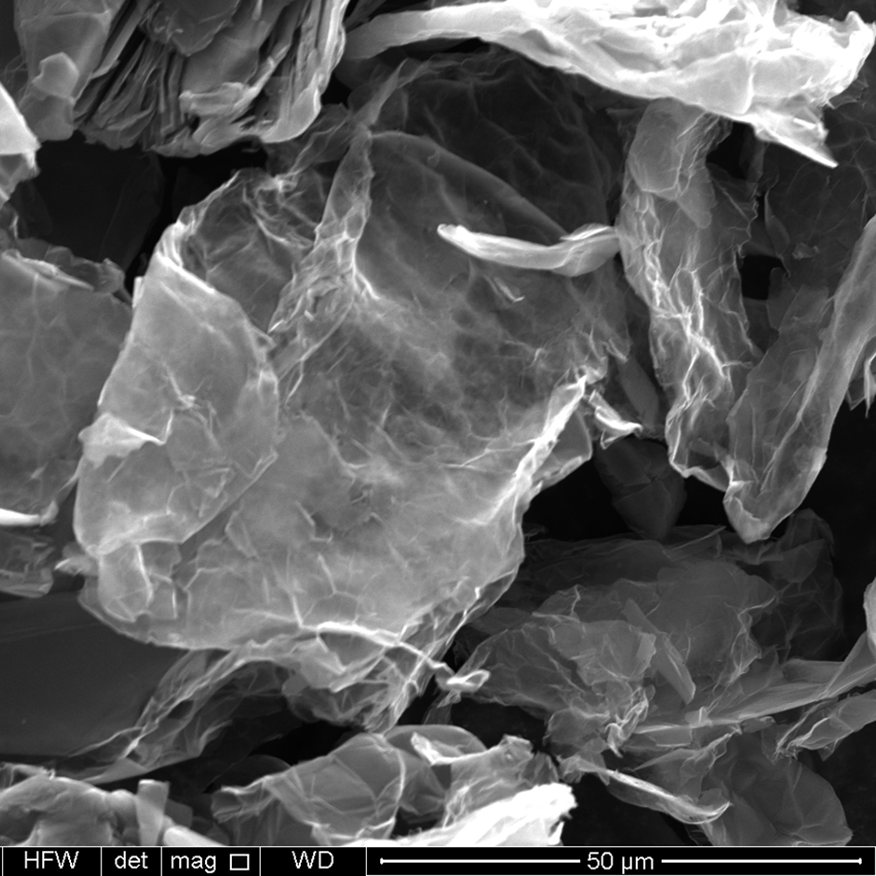

SEM image of the desalination material

Other Monash researchers have developed a sunlight responsive, ion-adsorbing material for desalinating salty or brackish water. This is an environmentally friendly and low cost solution for deployment in remote regions and in emergency situations that recharges its desalinating capacity on exposure to sunlight.

The development of more powerful, lighter batteries and lighter, stronger materials are being intensively researched and will be necessary to make electric aviation a reality. Gelion Technologies is a company that is commercialising gel-based zinc–bromine batteries. They are cheaper and safer than lithium ion batteries, have low fade capability even at high temperatures and are fire retardant.

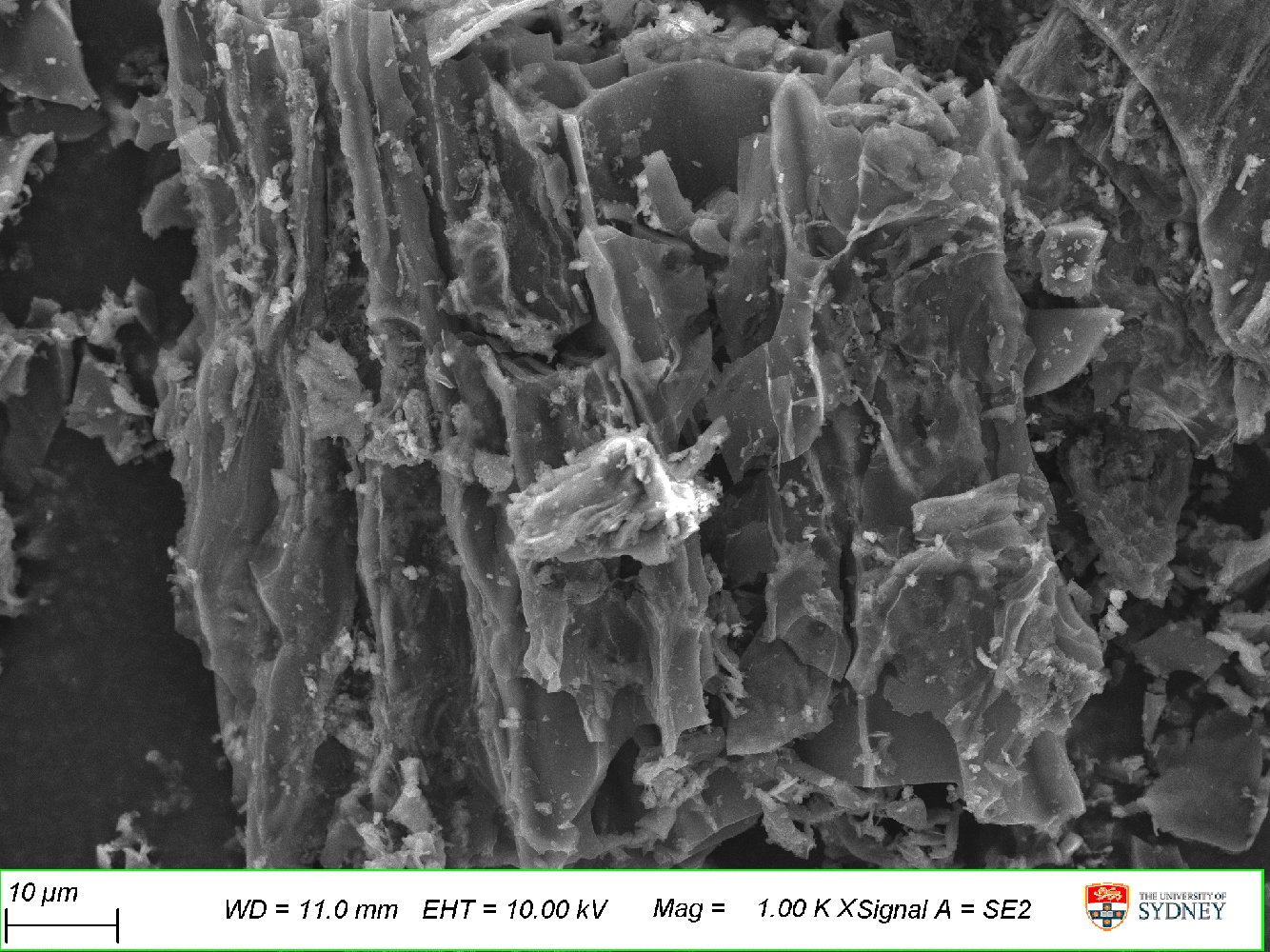

Scanning electron micrograph of the durian aerogel

A/Prof. Vincent Gomes, at University of Sydney, has developed a new method to create supercapacitors to store energy using biowaste from the world’s most repulsive smelling fruit – the durian. This creates a stable carbon aerogels that make significantly cheaper supercapacitors that are much faster charging than traditional batteries.

We have also supported many projects developing new aluminium–ceramic composites for aerospace applications, lighter and stronger aluminium, magnesium alloys, 3D printable titanium alloys, advanced high-strength steels, and materials reinforced with graphene, and cellulose fibres from native Australian spinifex grass.

Atomic scale transmission electron microscope image showing stacking faults and dislocations in a Mg alloy.

Wear Optimo’s micro wearable sensor.

We support spin-out company, WearOptimo, in their development of a revolutionary ‘sticker-like’ microneedle sensor to rapidly measure and report on IL-6 levels to predict dangerous cytokine storms before they happen. This technology can be applied to detect a wide range of diagnostic molecules but most immediately is designed to detect those COVID-19 patients most susceptible to cytokine storms so they can be prioritised for intensive care.

Atmo Biosciences too, has developed an ingestible sensor to monitor gut gases for the monitoring and diagnosis of a range of gastrointestinal conditions such as Irritable Bowel Syndrome, inflammatory bowel disease, carbohydrate malabsorption and intolerance. The tiny capsule sends its data in real time to provide real time direct sensing at known locations within the gut with more that 10,000-fold improved accuracy over current methods. It is also cheaper than all current methods and patient data can be aggregated for clinical analysis and predictive algorithms.

Carbon Cybernetics is commercialising a carbon-based neural implant that can be ‘injected’ into the brain to predict and manage seizures.

Microscopy Australia has supported the development of several projects, including working with Calix, who have invented the Calix Process for dramatically reducing carbon emissions from cement production.

Scanning electron microscope image of graphene sheets

We also work with graphene researchers and producers to enable them to understand how graphene can be used to strengthen materials, such as concrete, so less cement is required, along with developing the world standard for powdered graphene.

In other research from the University of Sydney the researchers successfully created carbon dioxide-loaded cement using fly ash and waste glass to make an environmentally friendly cement.

Designing and making materials at the atomic scale enables the development of a range of quantum sensors. An international research collaboration lead out of UTS has used our microscopes and expertise to very finely position individual atoms in the super-thin materials and fine fibres needed to create quantum sensors.

We provided microscopy to the UWA researchers as they developed the technology at the heart of the spin-out company Hazer Group. The process they developed produces hydrogen and graphite from methane (natural gas). Capturing the carbon as graphite prevents its emission as carbon dioxide. In 2020 Hazer Group teamed up with the WA state government to turn methane from wastewater treatment into 100 tonnes of fuel-grade hydrogen and 380 tonnes of graphite each year.

To further enable the hydrogen economy, researchers at the University of Sydney, working in partnership with CITIC Metals, have used Microscopy Australia’s state-of-the-art cryogenic atom probe to directly observe hydrogen at specific microstructures in steels. This is allowing them to design innovative steel suitable to store and transport hydrogen, overcoming the destructive and problematic hydrogen embrittlement.

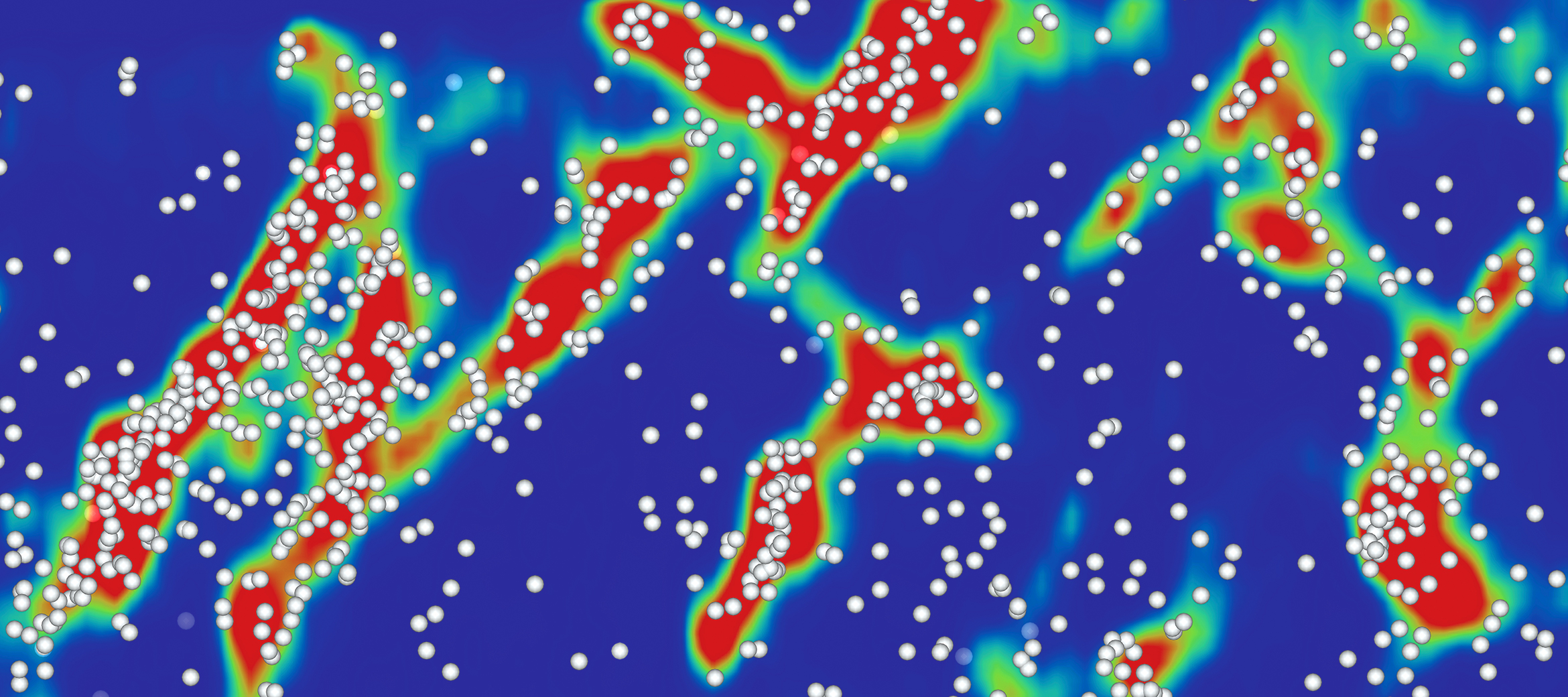

Visualisation of atom probe data showing the hydrogen atoms (white) collecting at dislocations (red).

University of Sydney researchers are working in partnership with CITIC Metals to develop design innovative steel suitable to store and transport hydrogen. This is a visualisation of atom probe data used in this research.

March 12, 2021